Water-stop and ash-retaining structure for comb-tooth plate expansion joints

A comb-tooth plate and water-stop technology, used in bridge parts, bridges, buildings, etc., can solve problems such as structural erosion and water damage, and achieve the effect of avoiding erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

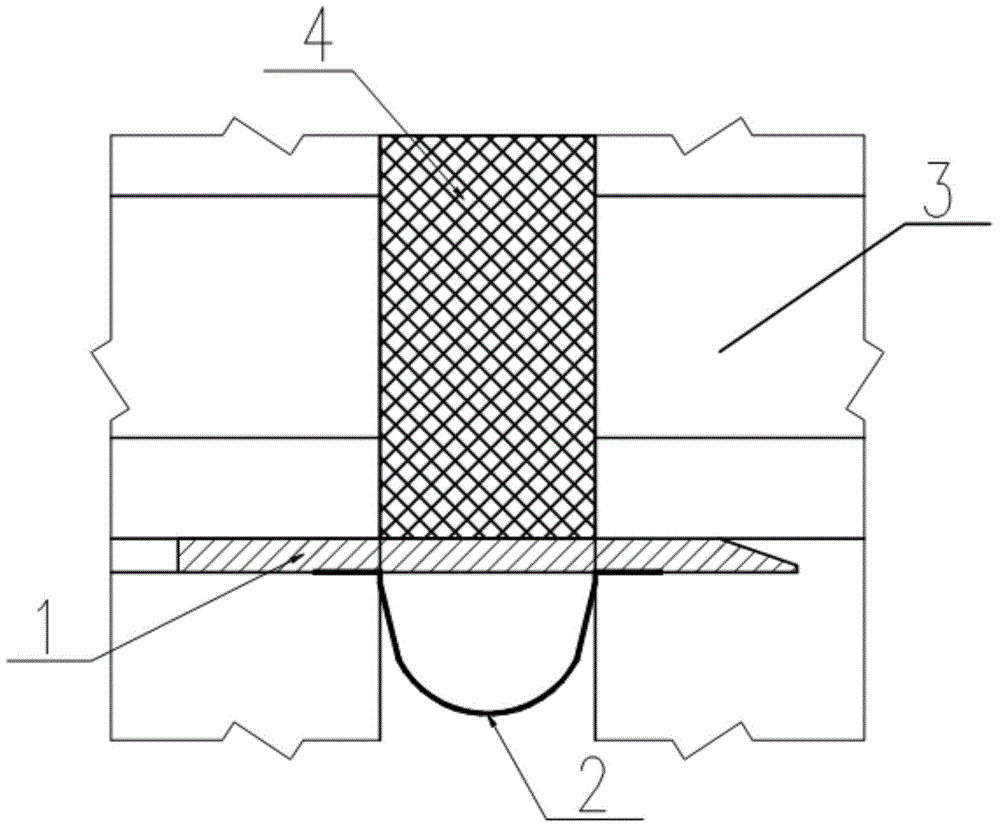

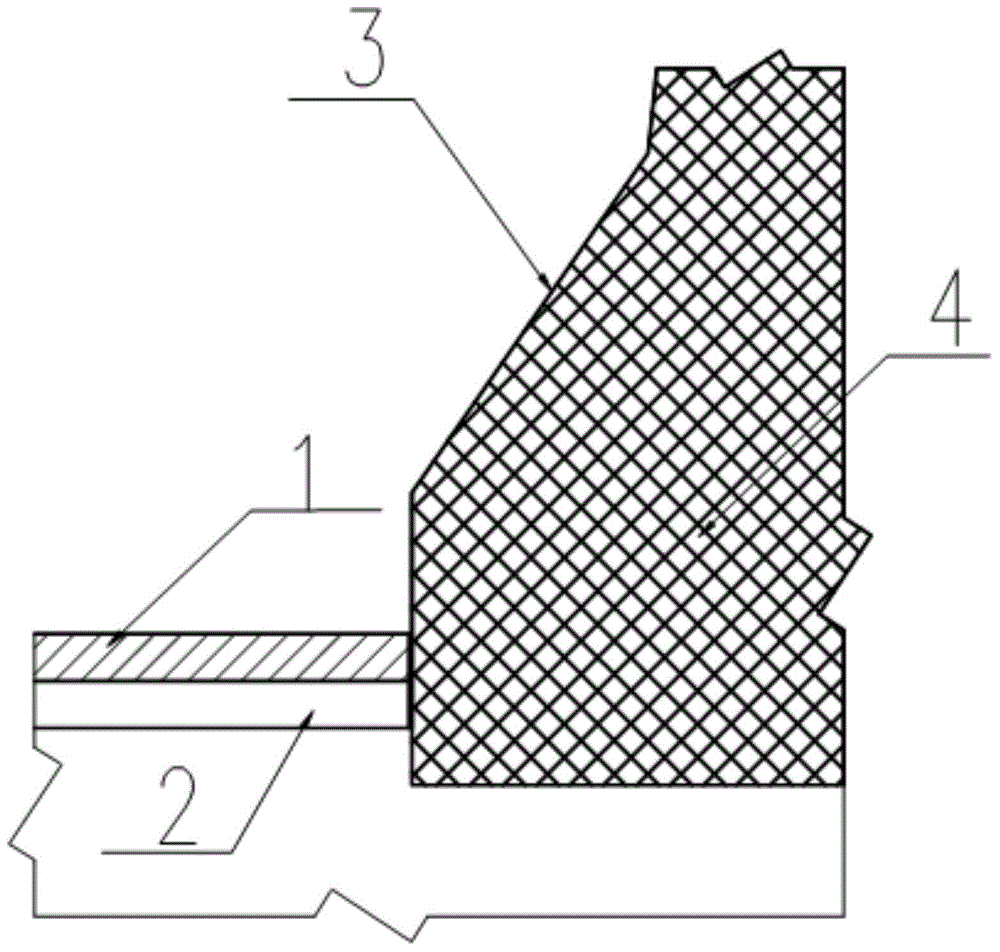

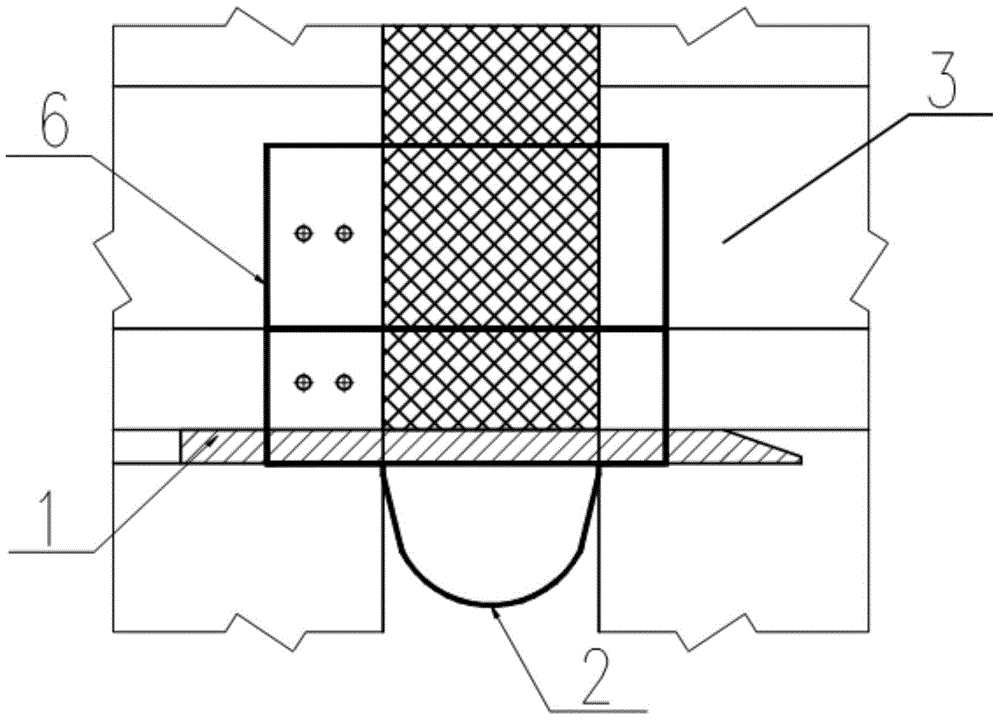

[0018] Figure 5 It is a schematic cross-sectional view of the water-stop and dust-retaining structure used on the expansion joints of the comb plate in this embodiment. Such as Figure 5 As shown, this embodiment proposes a water-stop and ash-retaining structure for comb-tooth plate expansion joints, including a water-stop rubber belt 2 laid on the comb-tooth plate expansion joints, and the water-stop rubber belt 2 is close to the anti-collision guardrail 3 The side edge of the side extends upwards to form an upturned section 5, and the upturned section 5 extends upwards along the inner edge of the anti-collision guardrail 3 and the gap between the anti-collision guardrail 3 and the comb plate 1, and as Figure 4 As shown, it is closely pasted on the anti-collision barrier 3, such as image 3 As shown, the outer surface of the upturned section 5 is also covered with a thin plate 6 that spans the gap of the crash barrier 3 and has the same linear shape as the inner edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com