Pressing type emulsion spray nozzle

A spray head, emulsion technology, applied in the direction of spray device, packaging, single handheld device, etc., can solve the problems of unfavorable spray head bottle mouth cleaning and environmental protection, waste of spray liquid, liquid dripping, etc., to achieve cleanliness and environmental protection, Good suction effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

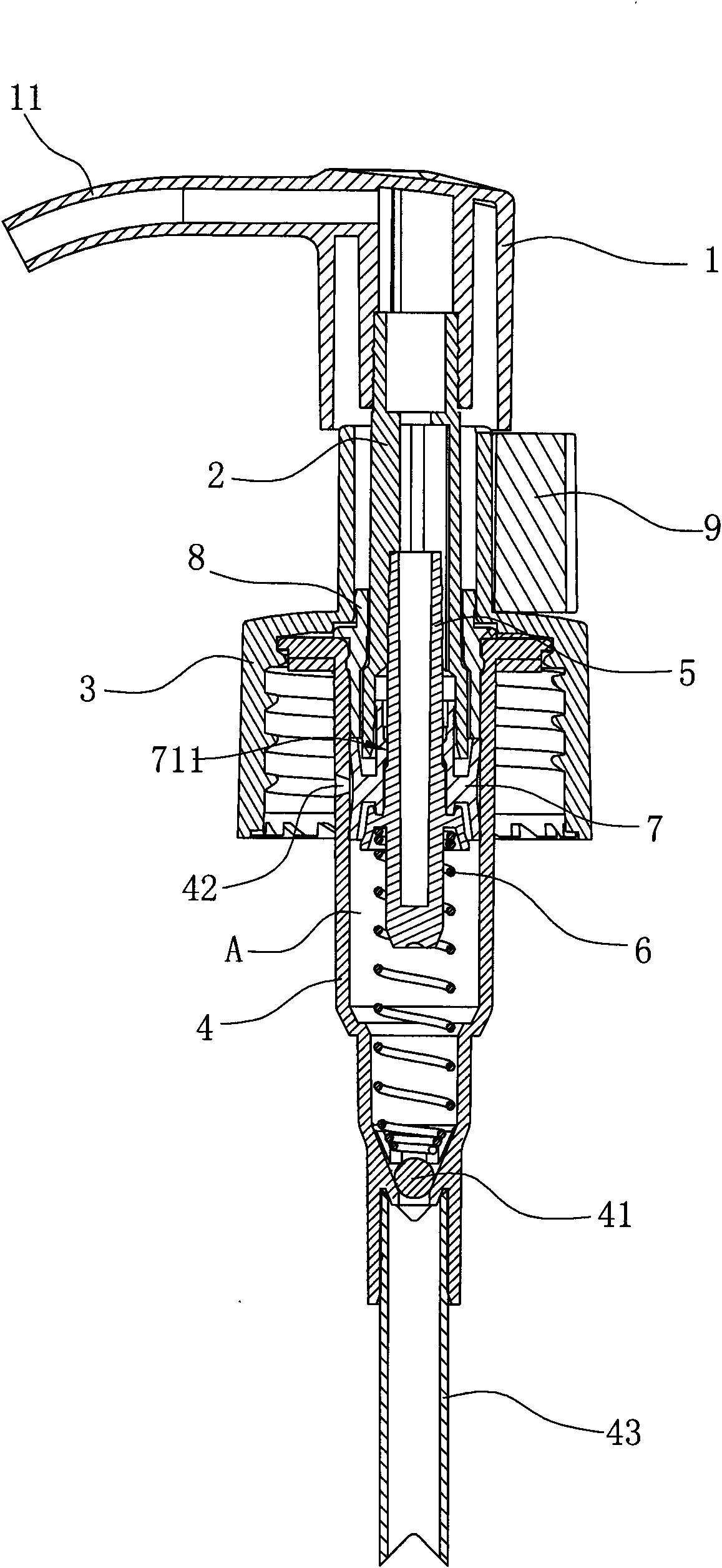

[0027] like Figure 1 to Figure 9 As shown, the emulsion nozzle of the present embodiment adopts a press type structure, and the nozzle includes a head cap 1, and the nozzle 11 is integrally formed on the head cap 1;

[0028] The valve stem 2 is connected to the head cap 1, the valve stem 2 is provided with a spray chamber which can communicate with the nozzle 11, and the outer side wall of the lower part of the valve stem 2 is formed with a convex stepped surface 21;

[0029] The bottle cap 3 is connected to the lotion bottle, and the bottle cap 3 is provided with a through hole in the axial direction;

[0030] The pump assembly includes a pump body 4, a push rod 5, a spring 6, a marble 41, a piston 7 and a ferrule 8, wherein the pump body 4 is arranged in the through hole, and the pump body 4 is provided on the side wall close to the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com