Transverse continuous heating system of coke oven

A heating system, coke oven technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

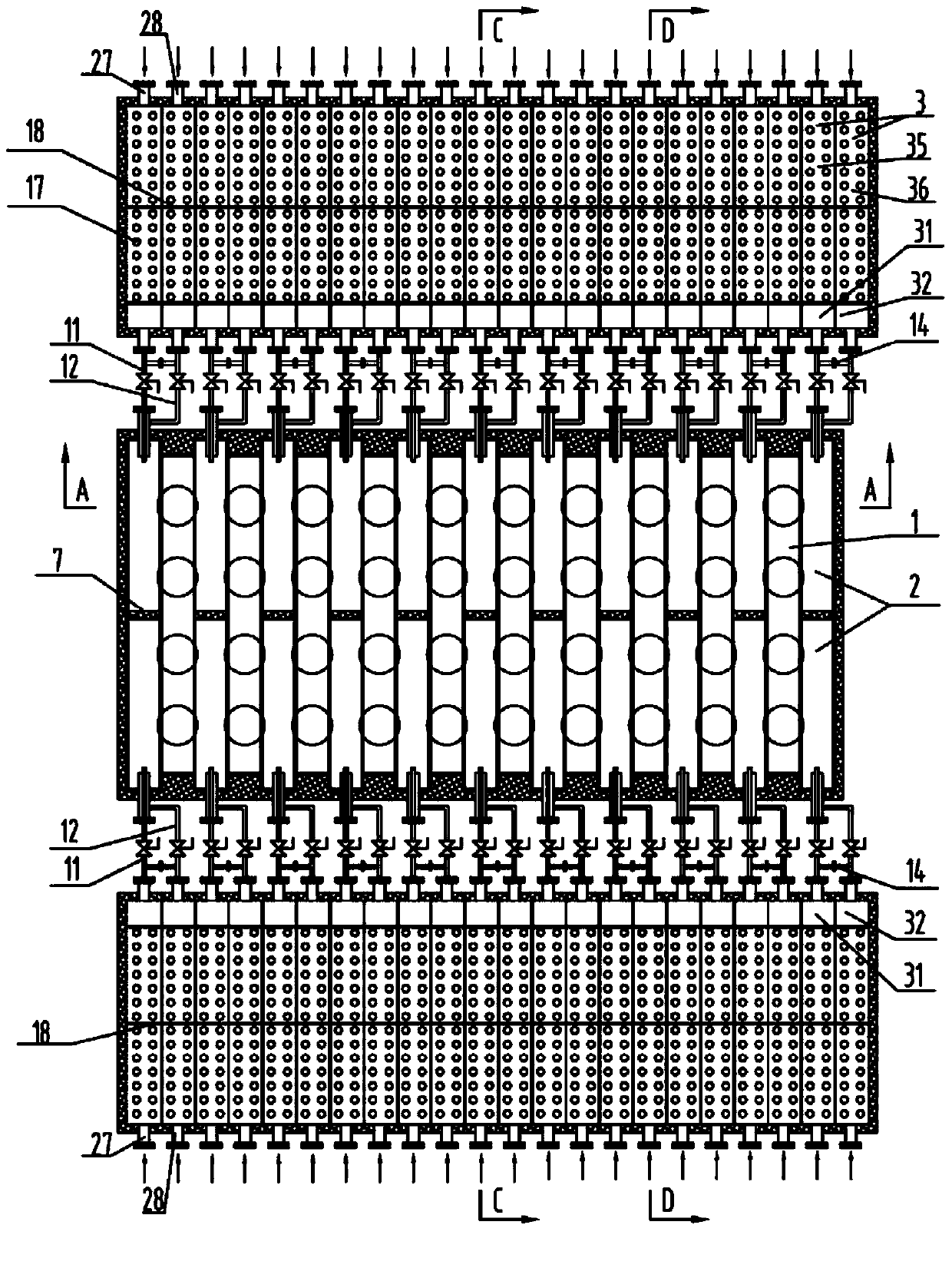

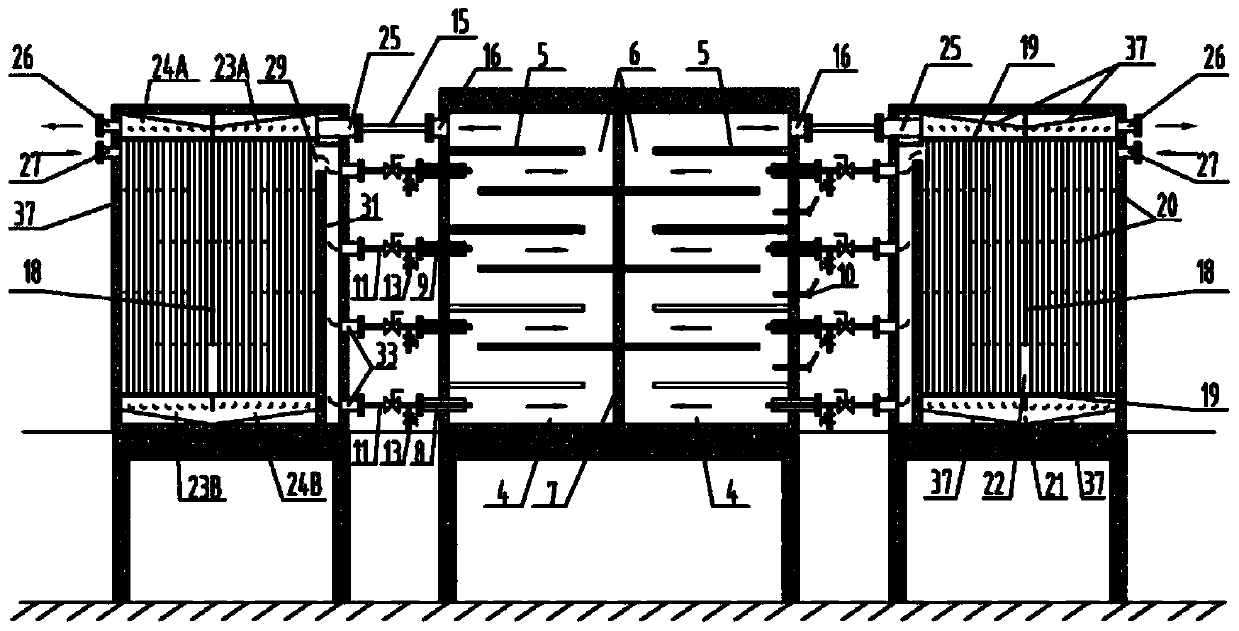

[0034] The detailed description of the present invention is as follows with reference to the drawings:

[0035] The transverse continuous heating system of the coke oven of the present invention is characterized in that it includes a combustion chamber 2 spaced apart from the coking chamber 1. The combustion chamber 2 is constructed of silica bricks in a cuboid shape, and a partition is provided in the center of the combustion chamber 2 Wall 7, which divides the combustion chamber 2 into left and right symmetrical left and right chambers;

[0036] The upper and lower chambers of each side are separated by partition bricks 5 into an even number of horizontal fire passages 4; from bottom to top, partition bricks 5 located between the first and second floors of horizontal fire passages 4 are close to the central partition wall 7. There are air holes 6, the partition brick 5 between the second and third levels of the horizontal fire path is close to the outer wall, leaving air holes 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com