Chemical fire retardant for controlling spontaneous combustion of lignite of power plant

A flame retardant and chemical technology, which is applied in the field of chemical flame retardants for the prevention and control of lignite spontaneous combustion in power plants, can solve the problems of reducing coal quality, good flame retardant effect, and large amount of coagulation accelerator, so as to prevent spontaneous combustion and reduce temperature rise speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

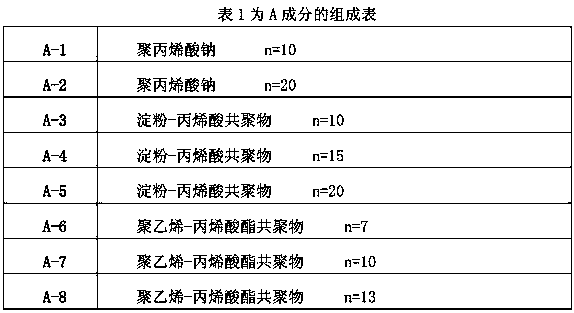

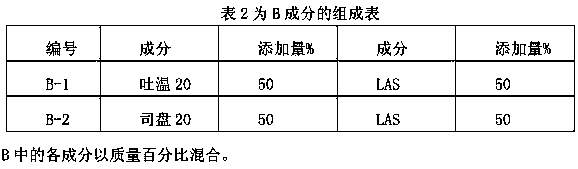

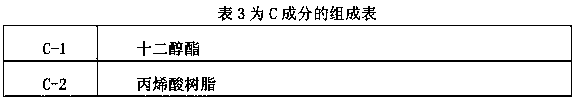

[0019] The chemical flame retardant for preventing spontaneous combustion of lignite in power plants in the present invention consists of component A, component B, component C and water, wherein component A is a polymer water-absorbing resin, component B is a surfactant, and component C is a film-forming agent. In the present invention, the mass percentage of component A is 0.5-1%, the mass percentage of component B is 0.1-0.5%, the mass percentage of component C is 0.1-0.5%, and the balance is water. The pH value of the chemical flame retardant in the present invention is between 5.0-7.0.

[0020] The water absorption capacity of component A in the present invention can be more than 500 times, and component A can be polyvinyl acetate, polyvinyl acetal, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com