A low-cost and easy-to-build putty construction technology

A construction technology and low-cost technology, applied in covering/lining, construction, filling slurry, etc., can solve the problems of single variety and poor quality of putty products, and achieve the effects of short drying time, easy scraping and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the novel low-cost easy-to-construct putty of the present invention comprises the steps of preparing materials and mixing materials, specifically comprising:

[0024] A. Raw material preparation: crush and sieve raw materials such as heavy calcium, fiber, lime, talcum powder, polymer, cement and refined sand for subsequent use;

[0025] B. Mixing: Mix and stir the crushed and sieved raw materials and other raw materials according to the mass ratio to obtain the target product evenly.

[0026] The crushing and sieving described in the A step is to pass through a 10 mesh sieve.

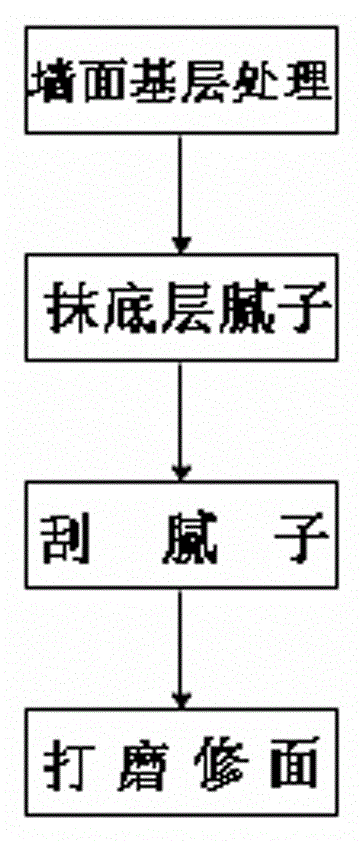

[0027] The construction process of the novel low-cost and easy-to-construct putty described in the present invention comprises the steps of wall base treatment, plastering the base layer putty, scraping the putty, and grinding and repairing the surface, specifically including:

[0028] A. Treatment of the wall base: clean the dust, dirt, splashes and mortar flow marks o...

Embodiment 1

[0051] The raw materials of heavy calcium, wood fiber, lime, talcum powder, latex powder, cement, and refined sand are respectively crushed through a 10-mesh sieve, and the weight of heavy calcium is 5Kg, wood fiber is 1.3Kg, lime is 25Kg, glue is 0.1Kg, talcum powder is 4Kg, latex powder 3Kg, 3Kg of cement, 50Kg of refined sand and 0.4Kg of water were mixed and stirred evenly to obtain the target new low-cost construction putty.

Embodiment 2

[0053] The raw materials heavy calcium, tough tensile fiber, lime, talcum powder, water retaining agent, cement, and refined sand are respectively crushed through a 10-mesh sieve, and the heavy calcium is 10Kg, tough tensile fiber is 2Kg, lime is 30Kg, glue is 0.2Kg, and talcum powder is 5Kg. , 4.5Kg of water-retaining agent, 5Kg of cement, 65Kg of refined sand and 0.5Kg of water were mixed and stirred evenly to obtain the target new low-cost construction putty.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com