A device with multiple inserts placed into the mold at one time

A technology of inserts and molds, applied in the field of devices with multiple inserts put into the mold at one time, to achieve the effects of stable injection molding cycle, improved product quality, and reduced operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

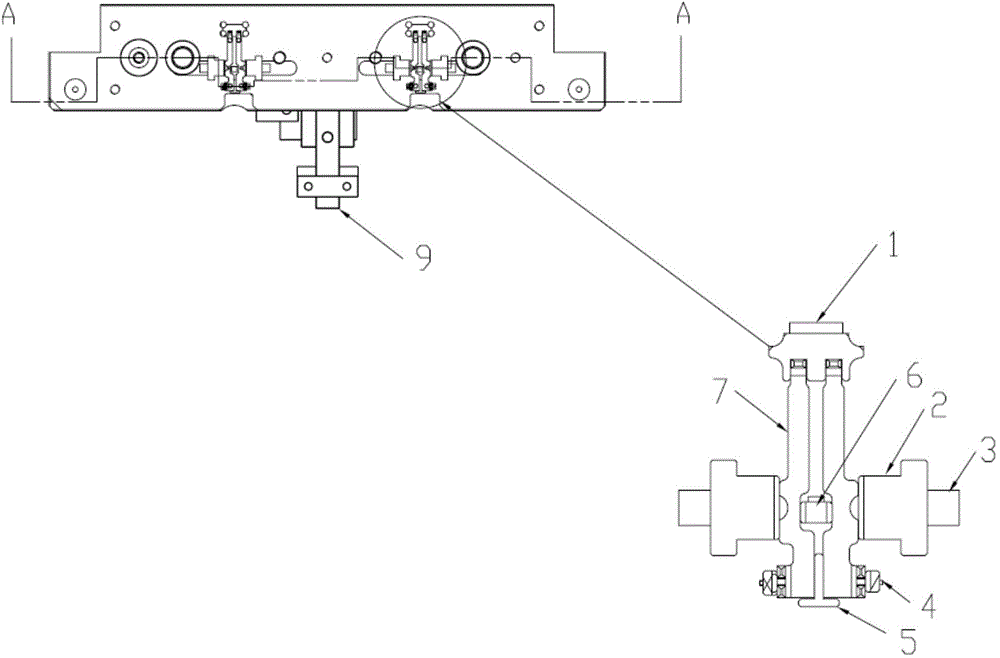

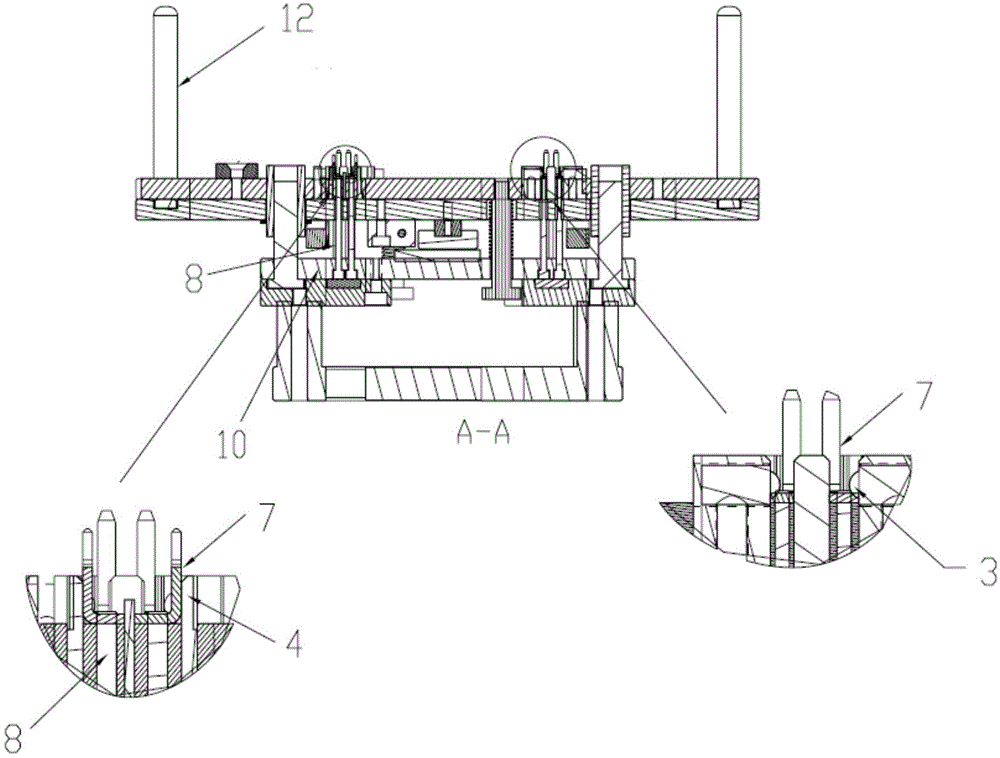

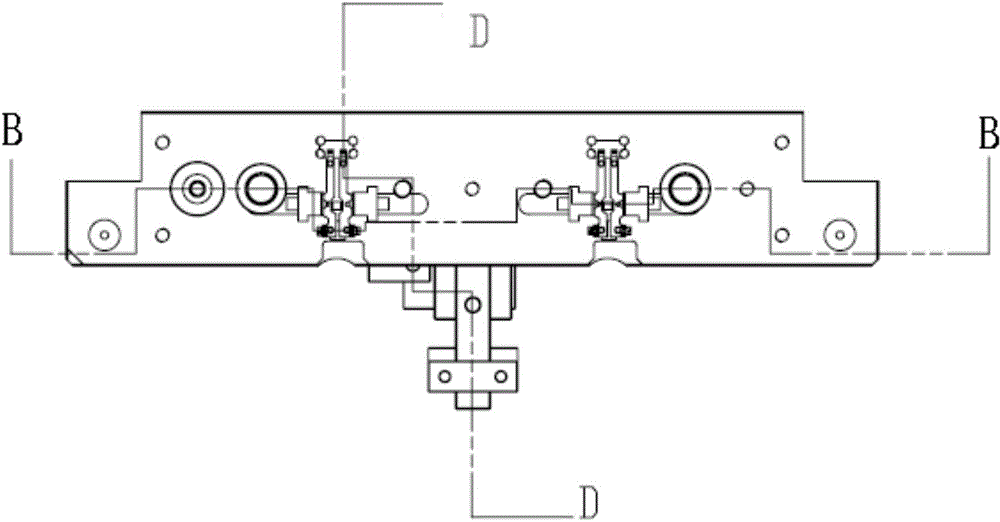

[0026] like Figure 1 to Figure 10 As shown, a device with multiple inserts put into the mold at one time, including the first pipe position 1, the second pipe position 2, the third pipe position 4, the fourth pipe position 5, the fifth pipe position 6, the first Elastic movable jackscrew 3, insert 7, thimble 8, sliding limit workpiece 9, thimble guide post fixed plate 10, first guide post 12, second elastic movable jackscrew 22, limit block 14, rotating handle 13, Linear guide rail, pipe position workpiece, return spring 19, limit screw 20, first linear bearing 16, second guide post 21, phenolic resin handle 15, clamp 23, fixing bracket 24, second linear bearing 25, first mold Cavity hole 26, second mold cavity hole 27, mold cavity 28;

[0027] Insert placement fixture positioning structure, thimble ejection structure has a sliding limit workpiece 9 to control the thimble to push the insert 7 by the external action, insert 7 is put into the fixture, there are first pipe posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com