High-precision advanced welding robot mechanism with six degrees of freedom

A welding robot, high-precision technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of small working space, short trouble-free running time, large cumulative error, etc., to improve reliability and Accuracy, good dynamic performance, effect of reducing bearing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

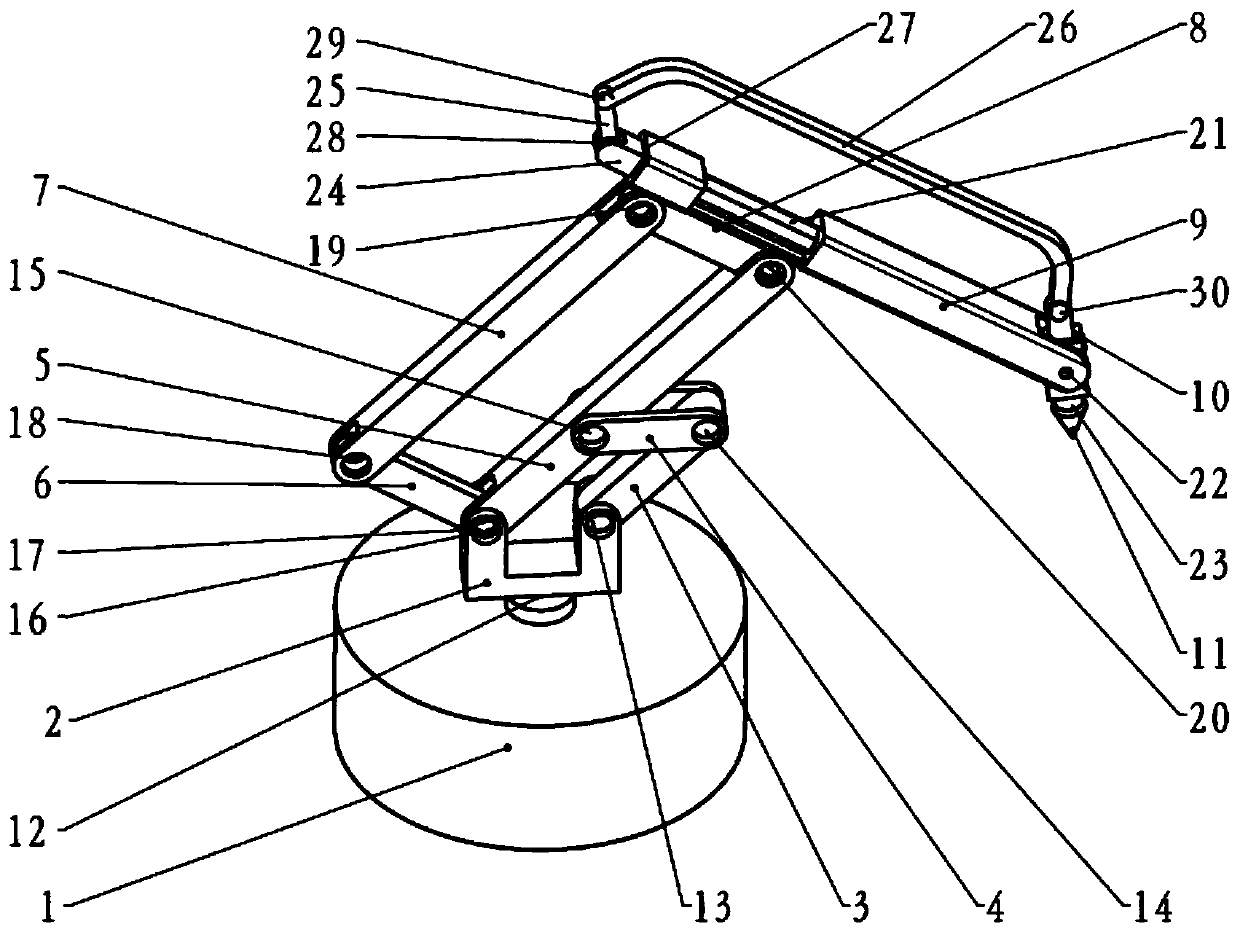

[0029] control figure 1 , 2 , 3 and 4, a six-degree-of-freedom high-precision advanced welding robot mechanism, consisting of a waist rotation mechanism, a shoulder swing mechanism, an elbow rotation mechanism, a forearm rotation mechanism, a wrist rotation mechanism, a welding torch holder rotation mechanism, machine base 1 and a rotary platform 2 composition.

[0030] control figure 1 , the waist turning mechanism of the robot is connected to the base 1 by the first rotating pair 12 through the rotating platform 2, and is driven by the first servo motor to realize the full-circle turning motion.

[0031] control figure 1 , 2 , The shoulder swing mechanism is formed by connecting the rotating platform 2, the first active rod 3, the first connecting rod 4 and the second connecting rod 5. The first active rod 3 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com