Production technology for surface sandblasting of SMC shower pan

A surface sandblasting and production process technology, applied in the production process field of SMC shower basin surface sandblasting, can solve the problems of poor anti-skid performance and high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Please further describe the present invention below in conjunction with the accompanying drawings.

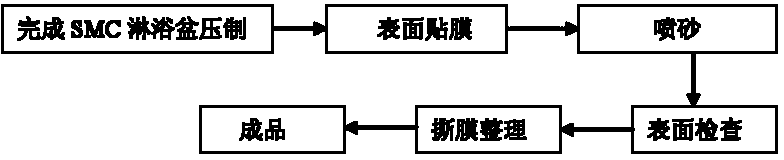

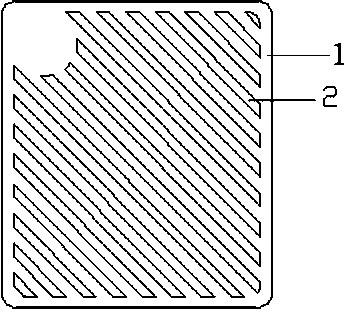

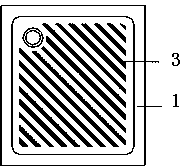

[0025] Such as figure 1 figure 1 Production process flow chart of the present invention, figure 2 The protective film on the surface of the SMC shower tray and image 3 The sandblasting effect of the surface of the SMC shower tray is shown in the picture,

[0026] A production process for sandblasting the surface of an SMC shower tray, at least comprising the following steps:

[0027] The first step is to press the SMC shower tray. After the pressing of the SMC shower tray is completed, the SMC shower tray is cleaned and surface treated to remove waste edges and burrs to obtain a smooth SMC shower tray 1 .

[0028] In the second step, a layer of sandblasting protective film 2 is attached to the surface of the SMC shower tray 1, and the protective film on the parts to be sandblasted is removed according to the designed pattern for sandblasting, such as figure 2 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com