Expansion sleeve linkage compression mechanism

A technology of pressing mechanism and expansion sleeve, which is applied in the direction of expanding mandrel, metal processing machinery parts, clamping, etc., can solve the problems of cumbersome operation of pressing mechanism, and achieve simple, reasonable and compact structure, low manufacturing cost and fast The effect of expansion, positioning and compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

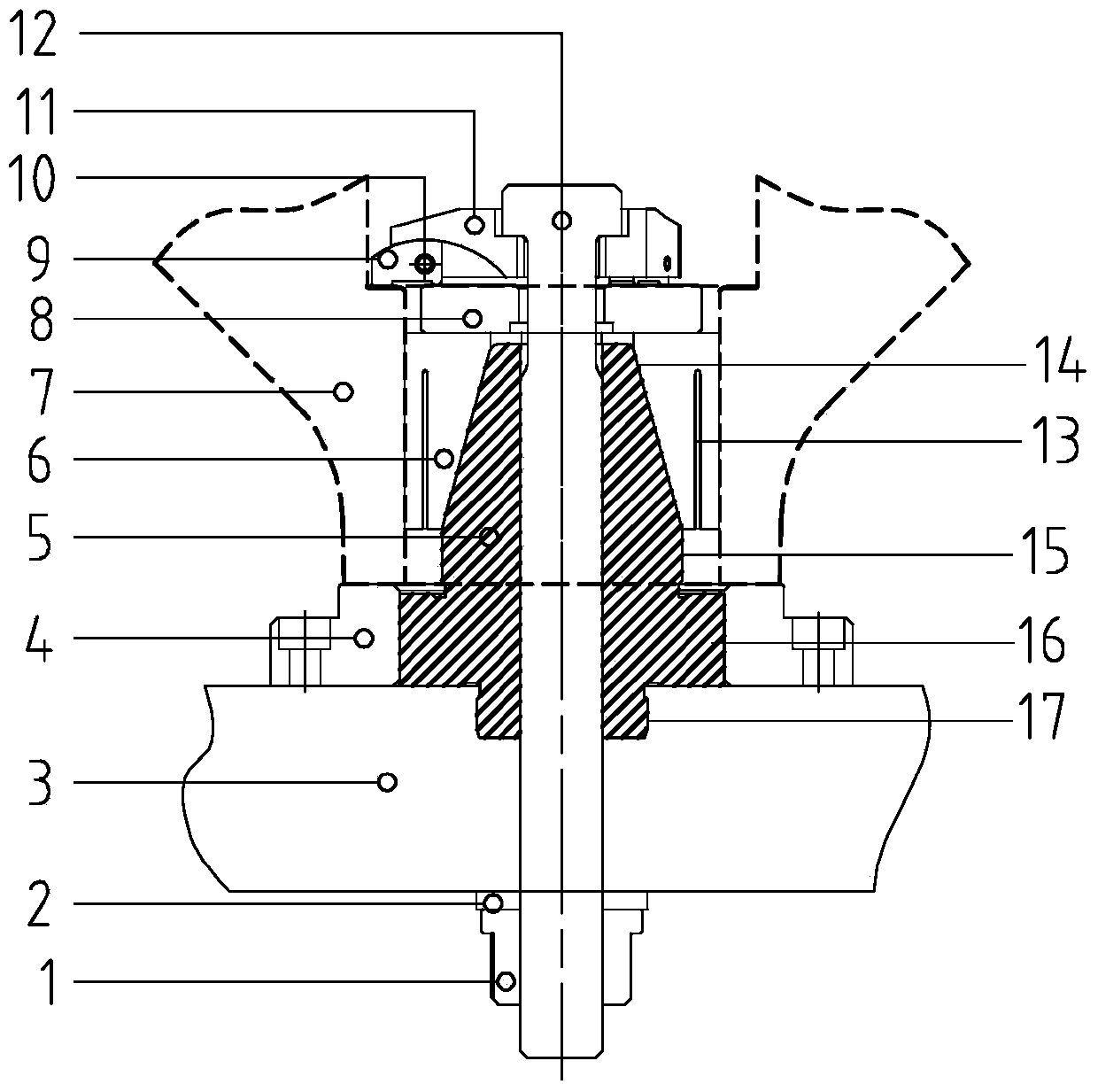

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] figure 1 Including lock nut 1, gasket 2, fixture plate 3, support block 4, tapered column 5, expansion sleeve, workpiece 7, expansion sleeve compression block 8, floating pressure plate 9, pin shaft 10, compression pressure plate 11 , Compression rod 12, annular opening groove 13, tapered surface 14, cylindrical surface 15, cylindrical boss 16, bottom support portion 17, etc.

[0014] Such as figure 1 As shown, the present invention is an expansion sleeve linkage compression mechanism, including a clamp plate 3, a rotary support block 4 is fixed on the upper part of the clamp plate 3, a tapered column 5 is arranged in the inner hole of the support block 4, and the cone The upper conical surface 14 of the shaped column 5 is provided with an expansion sleeve 6, and the upper plane of the expansion sleeve 6 is higher than the upper pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com