Direct connection welding mounting process for stainless steel-lined composite pipes

An installation process, stainless steel technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as leakage and corrosion at pipe joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be further described in detail below by describing the best embodiment with reference to the accompanying drawings.

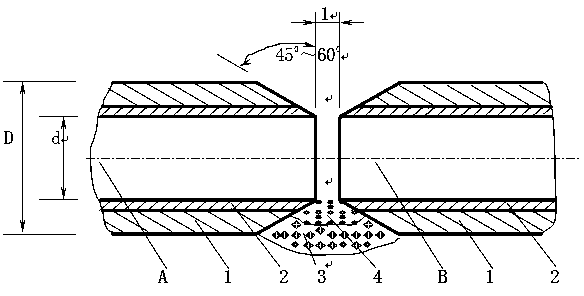

[0022] as attached figure 1 As shown, the stainless steel-lined composite pipe body is composed of inner stainless steel and outer carbon steel, sawing and port beveling 45 0 ~60 0 After grinding, the lined stainless steel composite pipes A and B are axially aligned and then fixed respectively. The cross-sectional distance between the two pipes is about 1mm. After the inspection is correct, use ordinary carbon steel electrodes to evenly and densely cover the welded stainless steel welding layer and weld firmly.

[0023] The present invention has been exemplarily described above in conjunction with the accompanying drawings. Obviously, the specific implementation of the present invention is not limited by the above methods, as long as various insubstantial improvements are made using the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com