Feed inducing agent for aquatic feed

An aquatic feed and food attractant technology, applied in the field of feed additives, can solve the problems affecting the flavor, palatability, indigestion, low digestion and absorption of the feed, etc., and achieve stable and controllable quality of raw materials, wide application of products, and good digestion. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preparation of yeast extract:

[0016] Every 10L of high-quality brewer's yeast, after filtering, removing impurities and debittering, centrifuged in a high-speed centrifuge at a speed of 4000r / min, centrifuged for 30min, after centrifuging, add 50000IU of papain and 100000IU of trypsin to the bacteria. Heat preservation reaction in the reaction chamber, the temperature is controlled at 45°C, and the reaction is 24 hours; then the temperature is raised to 95°C, and the heat preservation reaction is continued for 2.5 hours, 2 kg of rice bran is added, and then spray-dried. 250°C, the outlet temperature is 110°C, and the negative pressure is 90mpa, the yeast extract is obtained, and the obtained yeast extract is cooled and packaged.

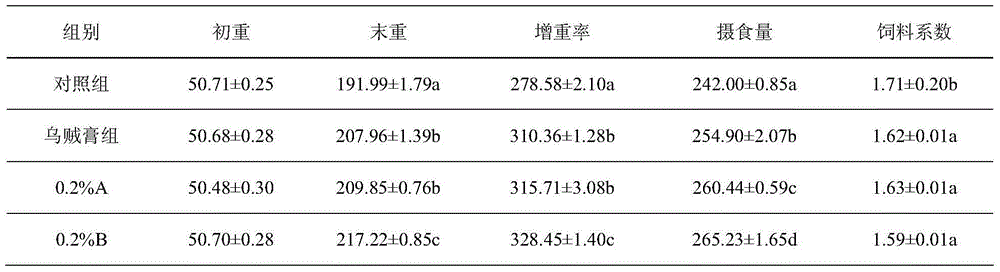

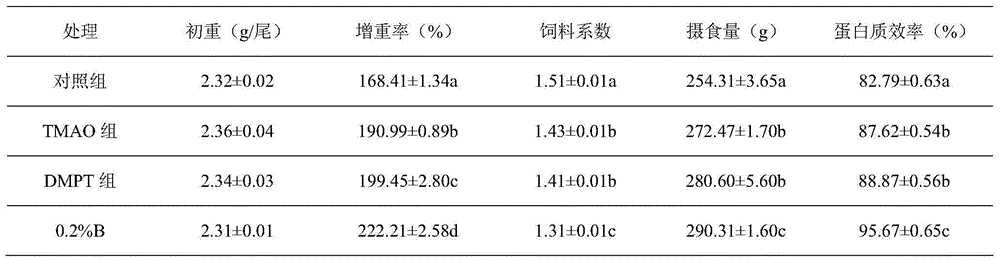

[0017] Based on the total mass fraction of 100%, yeast extract 40%, DMPT (dimethyl-thiatin propionate) 5%, TMAO (trimethylamine oxide) 30%, bile salt 5%, rice bran meal 20%, these The components are mixed and stirred evenly, and the aquatic...

Embodiment 2

[0019] Preparation of yeast extract:

[0020] Every 10L of high-quality brewer's yeast, after filtering, removing impurities and debittering, centrifuged in a high-speed centrifuge at a speed of 4000r / min, centrifuged for 30min, after centrifuging, add 50000IU of papain and 100000IU of trypsin to the bacteria. Heat preservation reaction in the reaction chamber, the temperature is controlled at 45°C, and the reaction is 24 hours; then the temperature is raised to 95°C, and the heat preservation reaction is continued for 2.5 hours, 2 kg of rice bran is added, and then spray-dried. 250°C, the outlet temperature is 110°C, and the negative pressure is 90mpa, the yeast extract is obtained, and the obtained yeast extract is cooled and packaged.

[0021] Based on the total mass fraction of 100%, yeast extract 50%, DMPT (dimethyl-thiatin propionate) 10%, TMAO (trimethylamine oxide) 20%, bile salt 10%, rice bran meal 10%, these The components are mixed and stirred evenly, and the aquat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com