Anti-adhesion medical material and method for producing same

A manufacturing method and anti-adhesion technology, applied in the fields of medical science, absorbent pads, surgical drugs, etc., can solve the problems of edema in the tissue, delayed tissue healing, unprepared bacterial infection, etc., and achieve the effect that harmful phenomena are not easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

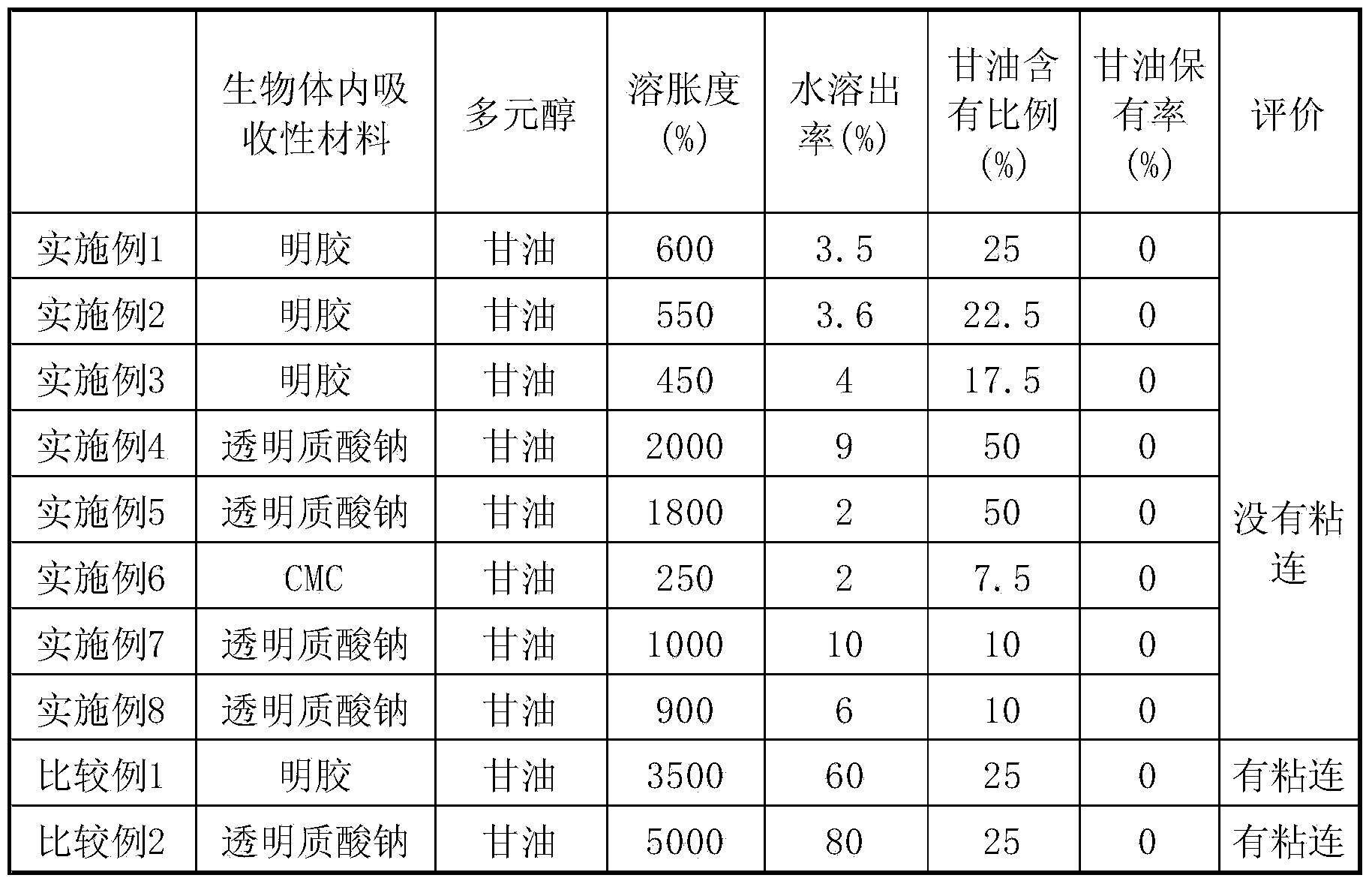

Embodiment 1

[0097] 10 g of acid process gelatin (derived from pigskin, manufactured by Sigma Chemicals) was dissolved in water to make the total amount 100 g to prepare a 10% gelatin aqueous solution. 30 g of the prepared aqueous gelatin solution was dispensed onto a 15 cm×15 cm tray whose inner surface was coated with polytetrafluoroethylene. The tray was placed in a dryer (trade name "Program Incubator IN800", manufactured by Yamato Scientific Co., Ltd.) set at 32° C., and the dispensed aqueous gelatin solution was air-dried to obtain 3 g of a gelatin film. The obtained gelatin film was poured into water cooled to 5° C. to be hydrated, and then 20 kGy of γ-rays was irradiated to perform water insolubilization treatment on the gelatin film. The degree of swelling of the water-insolubilizing gelatin film was 600%, and the water elution rate was 3.5%. The gelatin film treated with water insolubilization was immersed in 50 mL of 5% glycerin aqueous solution for 3 times for 2 hours each tim...

Embodiment 2

[0099] Except having set the temperature of the dryer at 50° C., it was carried out in the same manner as in the above-mentioned Example 1, and a 3-g gelatin film was obtained. The obtained gelatin film was immersed in 100 mL of 5 volume % glutaraldehyde aqueous solution, and it was made to react at room temperature for 6 hours, and the gelatin film was water-insolubilized. The degree of swelling of the gelatin film treated with water insolubilization was 550%, and the water elution rate was 3.6%. After the gelatin film treated with water insolubilization was fully washed with water, it was immersed in 50 mL of 5% glycerin aqueous solution three times for 2 hours each time, so that the inside of the gelatin film retained 5% glycerin aqueous solution to obtain an anti-adhesion medical material. The obtained medical material for anti-adhesion had a glycerin content rate of 22.5%, and a glycerin retention rate of 0%.

Embodiment 3

[0101] In the same manner as in the aforementioned Example 1, a 3 g gelatin film was obtained. The obtained gelatin film was immersed in 100 mL of an ethanol solution containing 5% by volume of hexamethylene diisocyanate, and reacted at room temperature for 18 hours to perform a water-insolubilizing treatment on the gelatin film. The degree of swelling of the water-insolubilizing gelatin film was 450%, and the water-eluting rate was 4.0%. After the gelatin film treated with water insolubilization was thoroughly washed with ethanol, it was immersed in 50 mL of 5% glycerin aqueous solution three times for 2 hours each time, so that the inside of the gelatin film was kept in 5% glycerin aqueous solution to obtain an anti-adhesion medical material . The obtained medical material for anti-adhesion had a glycerin content rate of 17.5%, and a glycerin retention rate of 0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com