Assessment device for fillet weld of end flange of GIS (gas insulated switchgear) and barrel and lossless assessment method

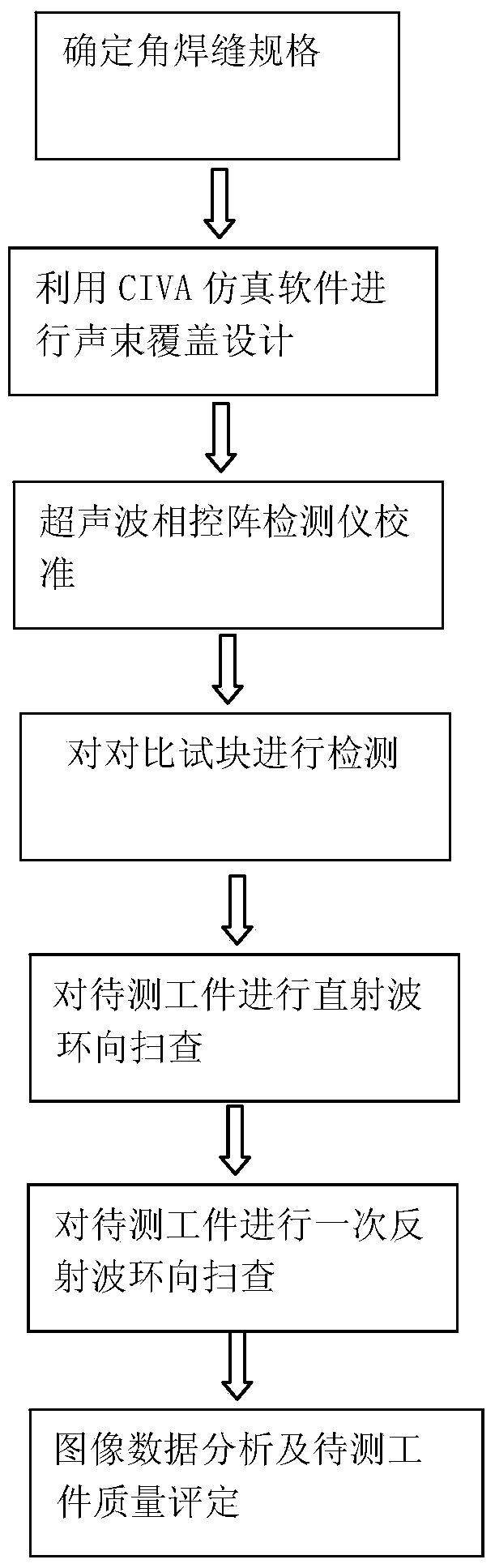

An evaluation device and a technology for fillet welds, which are applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problem of inability to detect internal air holes, unfused cracks, and the inability to effectively solve the non-destructive problems of end flanges and cylinder fillet welds Problems such as evaluation and inability to implement penetration testing, to achieve the effect of providing defect detection rate, easy discovery, and improving detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below through the accompanying drawings and specific embodiments. The following examples are only descriptive and not restrictive, and cannot be used to limit the protection scope of the present invention.

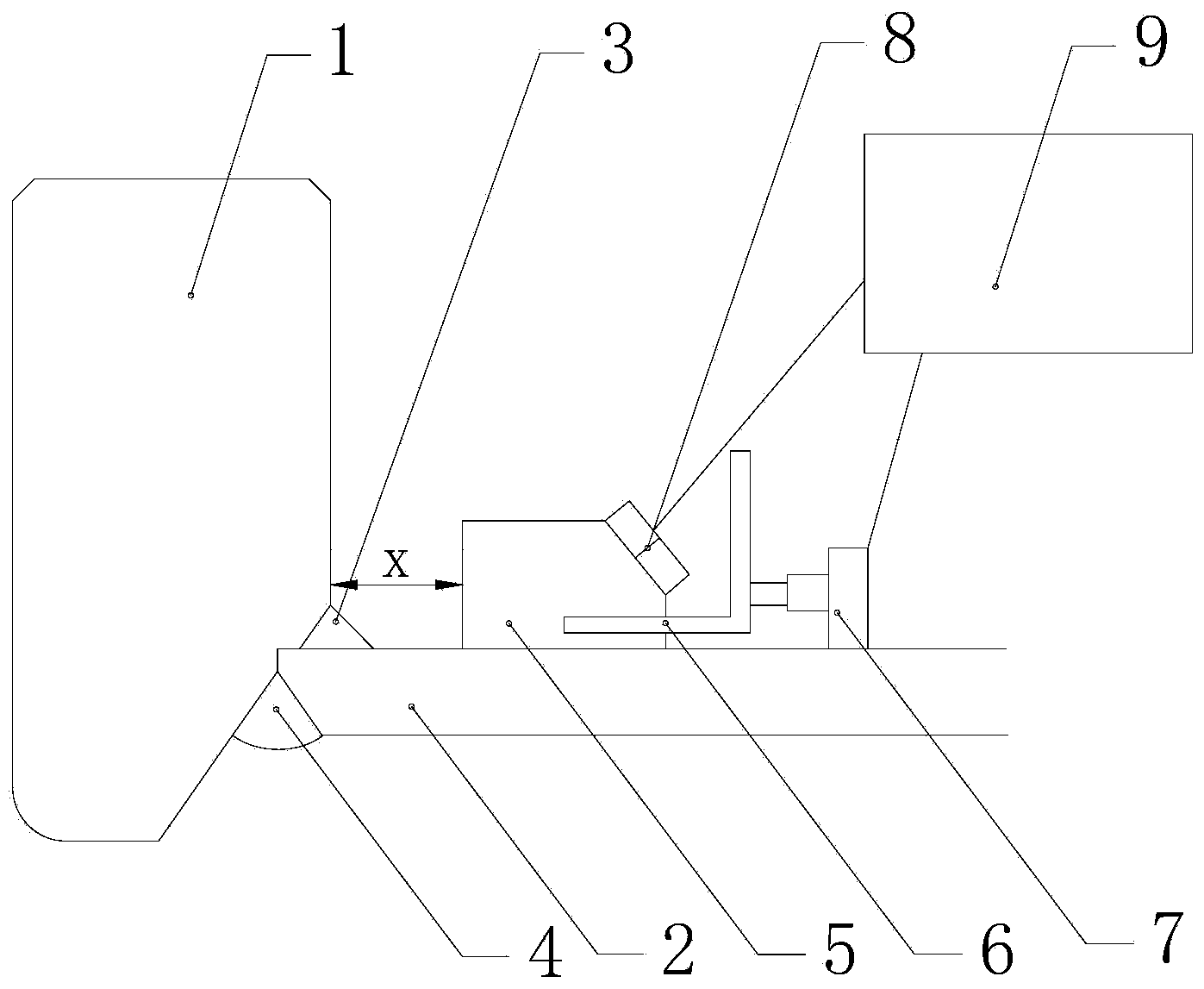

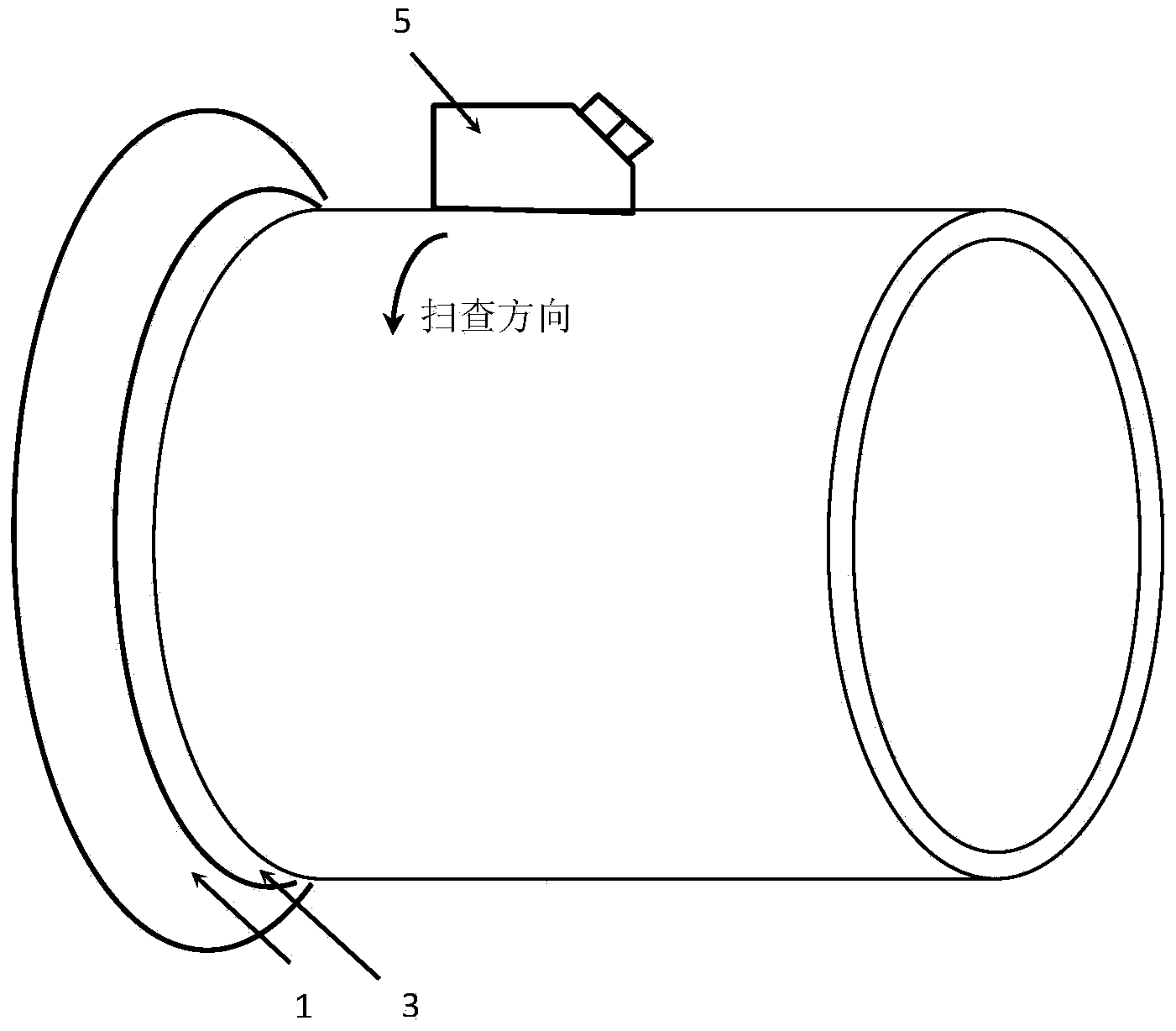

[0033] Such as Figure 1-2In the ultrasonic phased array evaluation device for the GIS end flange and cylinder fillet weld shown, the scanning frame 6 is provided with two symmetrical positioning columns, and the housing of the wedge 5 is provided with two There are two symmetrically arranged positioning holes, and the connection between the wedge block 5 and the scanning frame 6 is realized through the cooperation of the positioning holes and the positioning columns. The encoder 7 is connected with the pin hole on the rear side of the scanning frame through its front pin shaft. The encoder 7 is a wheel-type incremental rotary encoder. The encoder 7 is connected to the ultrasonic phased array detector 9 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com