Contact type high-voltage electrical equipment temperature detection system

A high-voltage electrical and detection system technology, applied in the direction of thermometers, thermometers, and measuring devices that use electrical/magnetic components directly sensitive to heat. Achieve photoelectric isolation, remove electromagnetic interference, and achieve the effect of electromagnetic interference shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

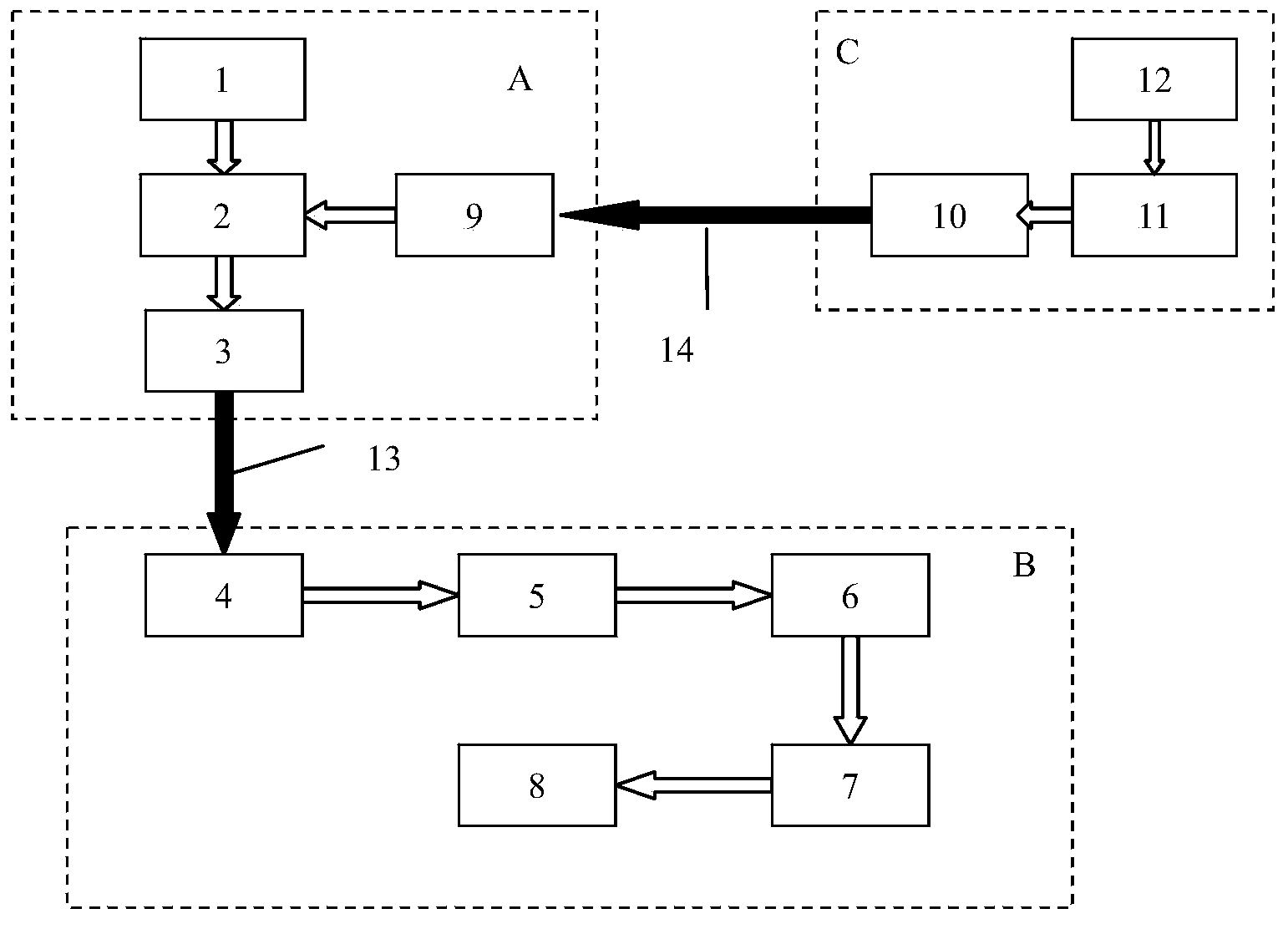

[0020] like figure 1 As shown, the embodiment of the present invention is provided with a temperature measurement module A, a signal processing module B and an energy light source module C. The temperature measuring module A is provided with a temperature sensor 1, a waveform generator 2, an electrical-optical conversion input port 3 and a solar panel 9; the signal processing module B is provided with an optical-electrical conversion output port 4, an operational amplifier 5, a voltage Comparator 6, single-chip microcomputer 7, liquid crystal display screen 8, described energy source module C is provided with parabolic mirror 10, metal halide lamp 11, 220V power supply 12; The output end of described temperature sensor 1 is connected the input end of waveform generator 2, The output end of the waveform generator 2 is connected to the electrical-optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com