Electro-hydraulic servo numerical control push rod device

A push rod device, electro-hydraulic servo technology, applied in servo motors, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of lack of force feedback control, long-term operation heat, high servo power, etc., to achieve precise motion accuracy , Long working time, large thrust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

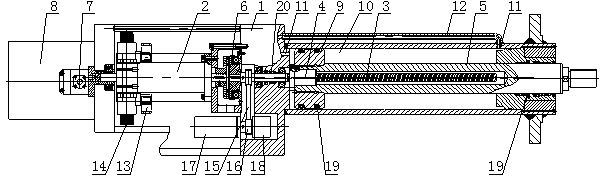

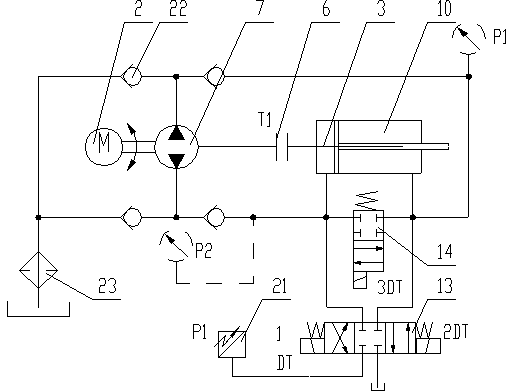

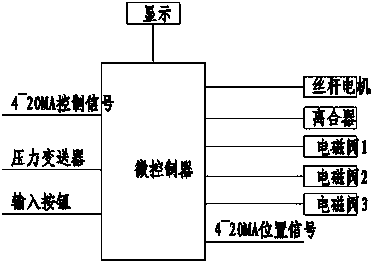

[0027] In specific implementation, such as figure 1 As shown, an electro-hydraulic servo numerical control push rod device includes a housing 1, a servo motor 2 located in the housing 1, the output shaft of the servo motor 2 is connected with a screw rod 3 arranged in the same axial direction, and the screw rod 3 is threaded The matching sleeve is provided with a nut 4, and also includes a push rod 5 coaxially fixed with the nut 4, wherein the servo motor 2 is a biaxial motor, and the output shaft connected between the servo motor 2 and the screw mandrel 3 is provided with a clutch 6 The output shaft at the end of the servo motor 2 away from the screw rod 3 is connected to an oil pump 7 and used as the power of the oil pump. The oil pump 7 is located in an oil tank 8 formed behind the housing 1; the outer eccentric fixing sleeve of the push rod 5 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com