A self-regulating nozzle type inflow control device

A technology of inflow control and nozzle, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of large resistance, time-consuming and labor-intensive, and small resistance, so as to improve oil well production, uniform inflow profile, reduce coning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

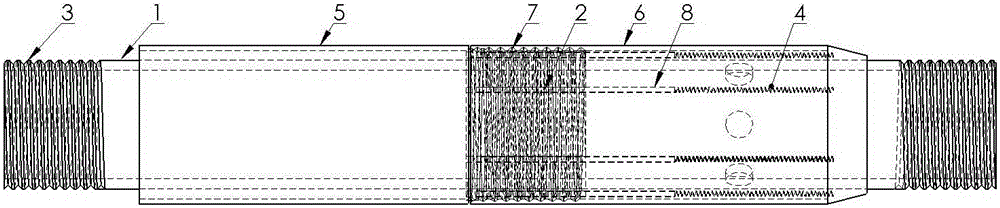

[0024] Below in conjunction with accompanying drawing, content of the invention will be further described:

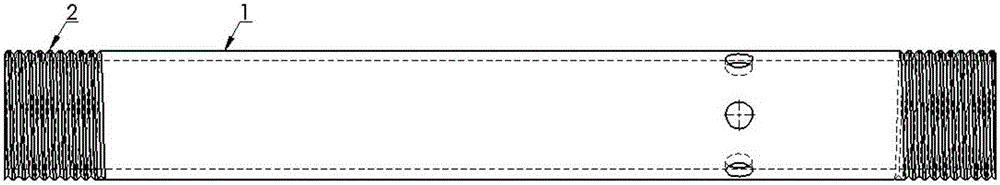

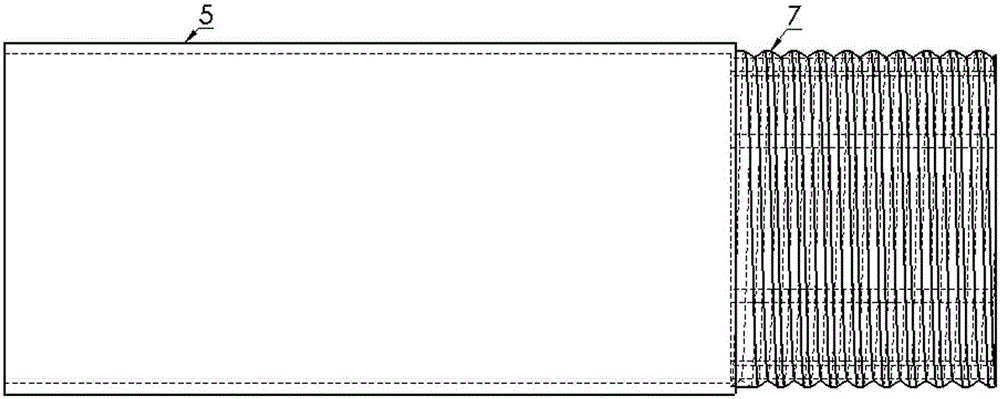

[0025] refer to Figure 1-Figure 5 As shown, the self-regulating nozzle type inflow control device includes a base pipe 1, a jacket and a throttle part 2. The base pipe 1 is connected to the connected oil pipe through the end threaded section 3, and the inner diameter is the same as that of the oil pipe. The base pipe 1 There are holes around the area corresponding to the spring 4 in the throttling part 2 as a passage for the fluid to flow into the base pipe 1. The jacket is divided into an upper jacket 5 and a lower jacket 6, which are connected by a middle thread 7. The upper jacket 5 is divided into Two parts with different inner diameters, the inner surface of the end with the larger inner diameter forms an annulus with the outer surface of the base pipe, which serves as a channel for fluid to flow from the oil jacket annulus to the nozzle, and the part with a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com