Viscosity-variable diverting acid for improving stratigraphic acidified section

A technology of turning to acid and profile, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of uniform acidification of difficult acid liquid, and achieve the effects of low surface tension, increased seepage resistance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

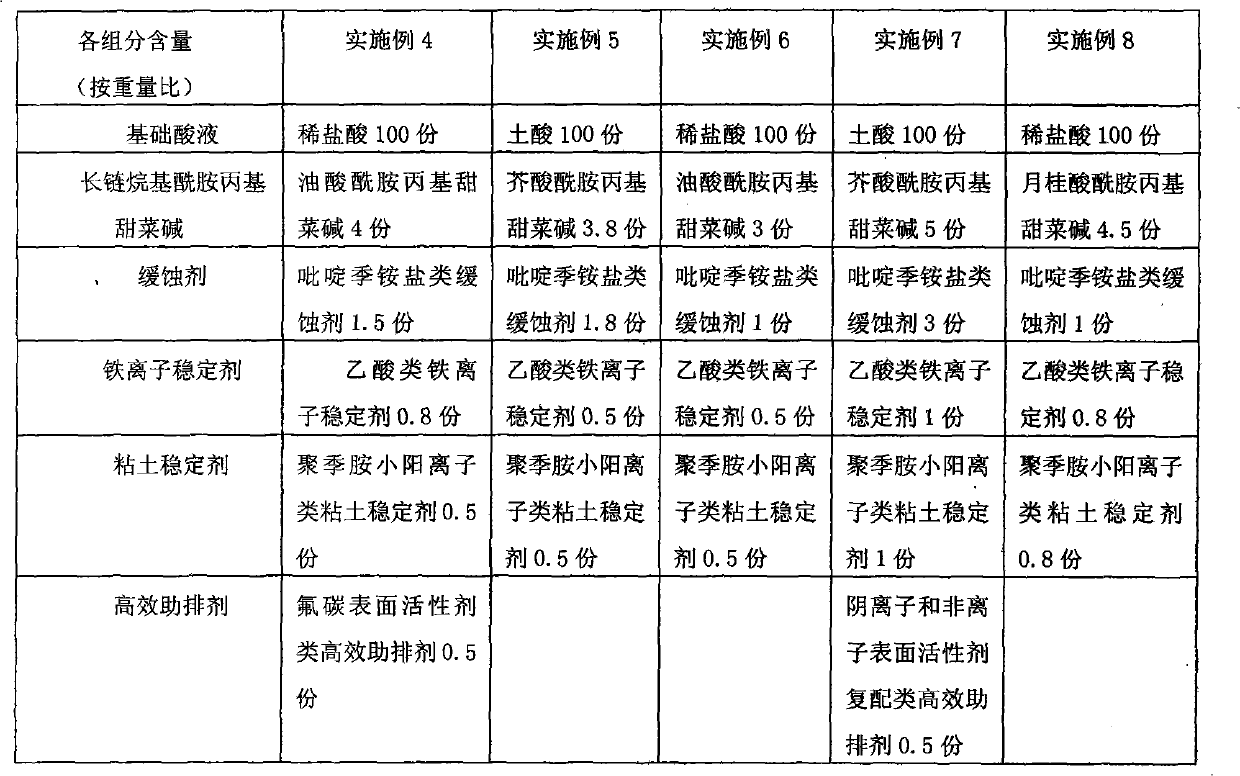

Examples

Embodiment 1

[0015] Example 1: A viscosity-increasing diverting acid for improving formation acidification profiles, which mainly contains the following components: 100 parts of basic acid liquid; 3.5 to 4.2 parts of long-chain alkyl amidopropyl betaine; 1.6 to 2.2 parts of corrosion inhibitor ; 0.7-0.85 parts of iron ion stabilizer; 0.75-0.92 parts of clay stabilizer. According to the numerical range of the above-mentioned content of each component, one of them is selected, and the components are combined and formulated.

Embodiment 2

[0016] Embodiment 2: A kind of viscous diversion acid that improves formation acidification profile, its preferred combination scheme is: basic acid liquid is 100 parts of dilute hydrochloric acid of mass concentration 15%-18%; Contains the oil of eighteen carbon chain hydrophobic bases 3.5-3.8 parts of acid amidopropyl betaine; 1.8 parts of pyridine quaternary ammonium acidification corrosion inhibitor; 0.8 parts of acetic acid complex iron ion stabilizer; 0.5 parts of polyquaternary ammonium small cationic clay stabilizer, initial viscosity 10- 12mPa.s. In this plan, it is best to choose dilute hydrochloric acid basic acid solution with a mass concentration of 15%-18%; oleic acid amidopropyl betaine with 18 carbon chain hydrophobic groups; corrosion inhibitor CRS-6 of pyridine quaternary ammonium salts; acetic acid Iron-like ion stabilizer NTS-2; polyquaternary amine small cationic clay-like stabilizer BCS-851; the viscosity-changing steering acid of this preferred combinati...

Embodiment 3

[0017] Embodiment 3: A kind of viscous diversion acid that improves formation acidizing profile, its optimal combination plan is: the base acid liquid is the dilute hydrochloric acid that contains mass concentration 10%-12% and the hydrofluoric acid of mass concentration 2%-3% 100 parts of clay acid; 4-4.5 parts of erucamide propyl betaine containing 22 carbon chain hydrophobic groups; 1.5 parts of pyridine quaternary ammonium salt corrosion inhibitor; 0.9 parts of acetic acid complex iron ion stabilizer ; 0.5 part of polyquaternary amine small cationic clay stabilizer; 0.5 part of high-efficiency drainage aid of fluorocarbon surfactant, initial viscosity 11-13mPa.s. In this solution, 0.5 part of fluorocarbon surfactant-based high-efficiency drainage aid is added, which is more conducive to the flowback of residual acid. The viscous turning acid of this optimal combination scheme is at 20°C for 100s -1 The apparent viscosity measured by Brookfield DV-III rotational viscometer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com