A kind of antistatic emulsified lubricating oil

A lubricating oil and antistatic technology, applied in the field of textile printing and dyeing, can solve the problems of single function of printing and dyeing auxiliaries, unable to play lubricating and antistatic, unable to solve at the same time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

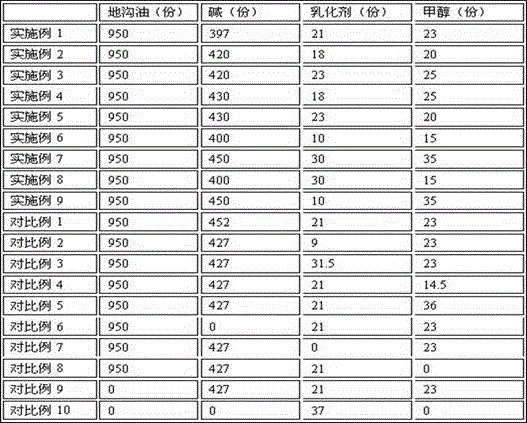

[0028] Embodiment 1-9, comparative example 1-10;

[0029] Table 1:

[0030]

[0031] ; In table 1, the parts are parts by weight, and the waste oil used is the fatty acid that the C chain length of extracting from waste oil is 10-18; The alkali used is that sodium hydroxide and sodium carbonate form according to the weight ratio of 1:1 The emulsifier used is AEO-3 (the test proves that the fatty alcohol emulsifier can meet the requirements of the present invention, and the effect has no obvious difference, here, only AEO-3 is taken as an example);

[0032] Prepare raw materials according to Table 1, prepare according to the following method:

[0033] (1) Stir the waste oil at 92°C for 31 minutes;

[0034] (2) Add alkali by dropwise addition, stir for 103 minutes after 3-6 hours of dropwise addition, and then raise the temperature to 126°C;

[0035] (3) Add emulsifier, then stir and keep warm for 107min;

[0036] (4) Add methanol and keep warm for 110 minutes; the produc...

Embodiment 10

[0038] Adopt the raw material ratio of embodiment 1, adopt following steps to prepare:

[0039] (1) Stir the waste oil for 20 minutes at 98°C;

[0040] (2) Add alkali by dropwise addition, stir for 150min after 6 hours of dropwise addition, and then raise the temperature to 136°C;

[0041] (3) Add emulsifier, then stir and keep warm for 120min;

[0042] (4) Add methanol and keep warm for 120 minutes to obtain the product;

[0043] The waste oil used is a fatty acid with a C chain length of 10-18 extracted from the waste oil; the alkali used is a mixture of sodium hydroxide and sodium carbonate in a weight ratio of 1:1; the emulsifier used is AEO-3.

Embodiment 11

[0045] Adopt the raw material ratio of embodiment 1, adopt following steps to prepare:

[0046] (1) Stir the waste oil for 20 minutes at 87°C;

[0047] (2) Add alkali by dropwise addition, stir for 60 minutes after 3 hours of dropwise addition, and then raise the temperature to 115°C;

[0048] (3) Add emulsifier, then stir and keep warm for 80 minutes;

[0049] (4) Add methanol and keep warm for 80 minutes to obtain the product;

[0050] The waste oil used is a fatty acid with a C chain length of 10-18 extracted from the waste oil; the alkali used is a mixture of sodium hydroxide and sodium carbonate in a weight ratio of 1:1; the emulsifier used is AEO-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com