A laser shock treatment method and device for a porous plate

A laser shock and processing device technology, applied in the field of metal processing, can solve the problems of difficulty in meeting the wear resistance requirements of pellet machine template, difficulty in achieving satisfactory impact effect, laser energy dispersion, etc. good impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

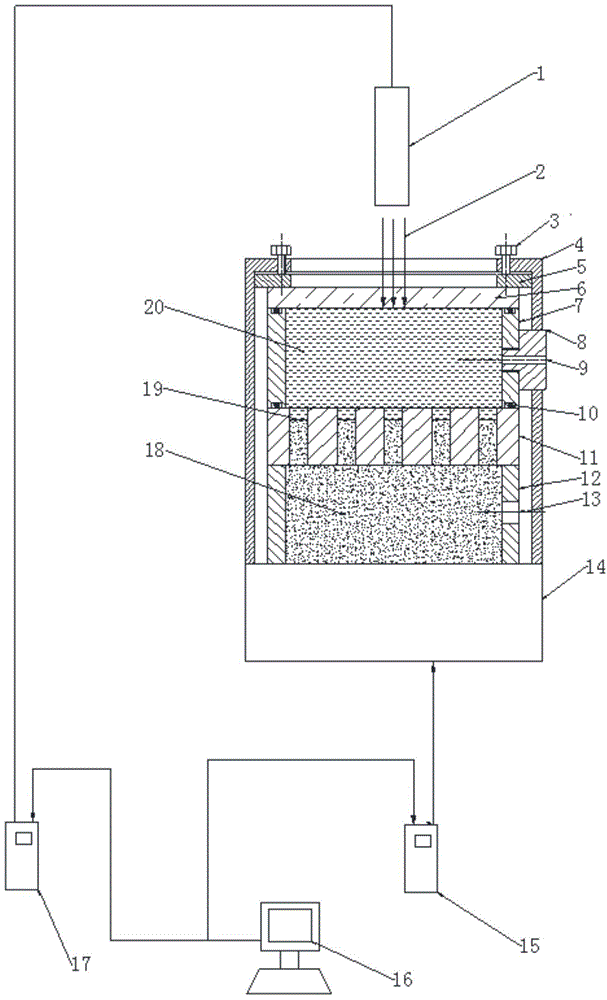

[0028] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

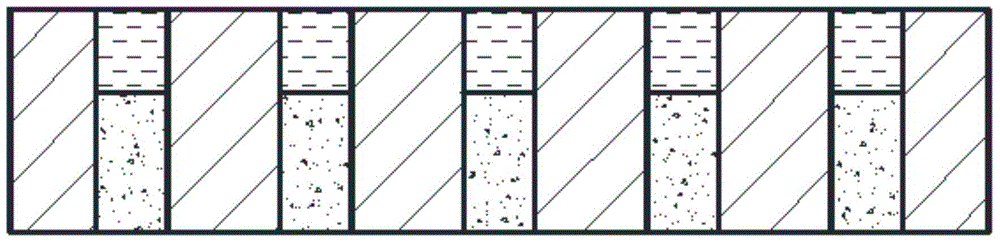

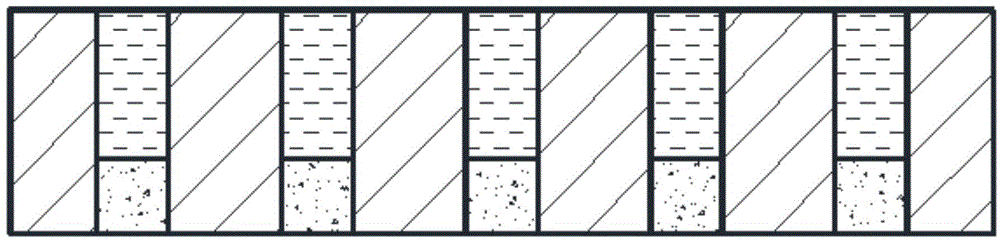

[0029] A kind of perforated plate laser shock treatment device, such as figure 1 As shown, it includes laser generator 1, compression screw 3, fixture 4, pressure plate 5, glass 6, water tank 7, water inlet pipe 8, sealing ring 10, workpiece 11, lower tube 12, workbench 14, workbench control device 15 , a computer 16, a laser generator control device 17, a viscoelastic fluid 18, and a transparent liquid 20; After the elastic fluid 18 and the viscoelastic fluid 18 pass through the holes on the porous plate workpiece 11 that need impact treatment, the upper surface thereof is slightly lower than the upper surface of the porous plate workpiece 11 or is flush with the upper surface of the workpiece 11, and the porous plate workpiece 11 is placed On the lower cylinder 12, the holes that need impact tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com