A kind of distillation method for reducing liquor ethyl lactate

A technology of ethyl lactate and distillation method, applied in the field of liquor brewing, can solve the problems of reducing the concentration of esterification reaction substrate, reducing ethyl lactate in liquor, energy consumption, etc. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

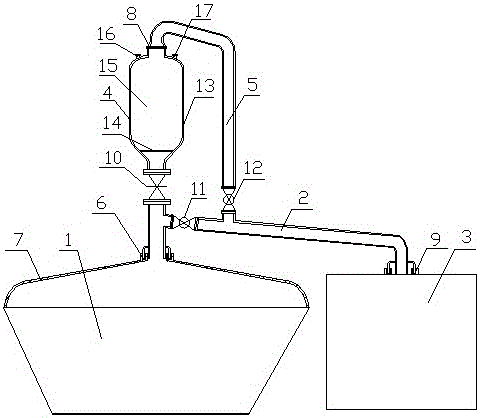

[0032]A distillation method for reducing ethyl lactate in liquor, comprising the steps of filling a steamer, distilling, and picking wine in sequence, the distillation step refers to distillation by using distillation equipment for reducing milk and improving quality of liquor, and the distillation equipment for reducing milk and improving quality of liquor includes a wine steamer 1 , 40 centimeters of tower heights, 30 centimeters of tower diameter packing towers 4, the first air-passing cylinder 2, the second air-passing cylinder 5 and the condenser 3, first close the first valve 10 and the third valve 12 of the milk-reducing and quality-improving liquor distillation equipment , open the second valve 11, the liquor steam in the wine retort 1 enters the first air-passing cylinder 2, then close the second valve 11, open the first valve 10 and the third valve 12, and the liquor vapor in the wine retort 1 enters the packed tower 4 , the packing support plate 14 of 20 meshes throu...

Embodiment 2

[0034] A distillation method for reducing ethyl lactate in liquor, comprising the steps of filling a steamer, distilling, and picking wine in sequence, the distillation step refers to distillation by using distillation equipment for reducing milk and improving quality of liquor, and the distillation equipment for reducing milk and improving quality of liquor includes a wine steamer 1 , 50 centimeters of tower heights, the packed tower 4 of 30 centimeters of tower diameters, the first air-passing cylinder 2, the second air-passing cylinder 5 and the condenser 3, first close the first valve 10 and the third valve 12 of the milk-reducing and quality-improving liquor distillation equipment , open the second valve 11, the liquor steam in the wine retort 1 enters the first air-passing cylinder 2, then close the second valve 11, open the first valve 10 and the third valve 12, and the liquor vapor in the wine retort 1 enters the packed tower 4 , the packing support plate 14 of 60 objec...

Embodiment 3

[0036] A distillation method for reducing ethyl lactate in liquor, comprising the steps of filling a steamer, distilling, and picking wine in sequence, the distillation step refers to distillation by using distillation equipment for reducing milk and improving quality of liquor, and the distillation equipment for reducing milk and improving quality of liquor includes a wine steamer 1 , 60 centimeters of tower heights, the packed tower 4 of 30 centimeters of tower diameters, the first gas-passing cylinder 2, the second gas-passing cylinder 5 and condenser 3, first valve 10 and the 3rd valve 12 of the first valve 10 and the 3rd valve 12 of the distilling equipment for reducing milk and improving quality are closed earlier , open the second valve 11, the liquor steam in the wine retort 1 enters the first air-passing cylinder 2, then close the second valve 11, open the first valve 10 and the third valve 12, and the liquor vapor in the wine retort 1 enters the packed tower 4 , the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com