Chemical sealing rubber plug in snubbing operation string as well as preparation method and application of chemical sealing rubber plug

A pressurized operation and chemical technology, applied in chemical instruments and methods, earthwork drilling, sealing/isolation, etc., can solve problems such as the limitation of the perfection of the plug, poor sealing effect, and inability to pass through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

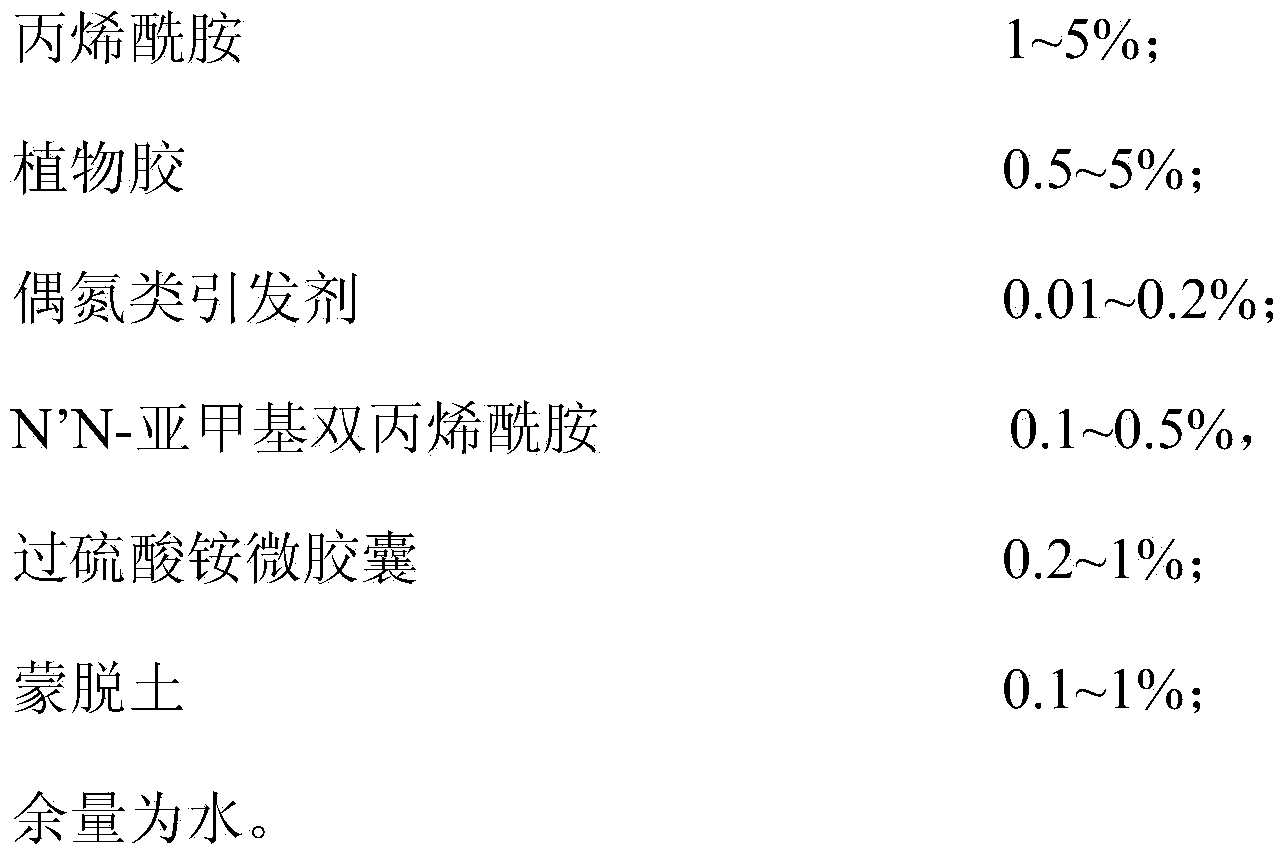

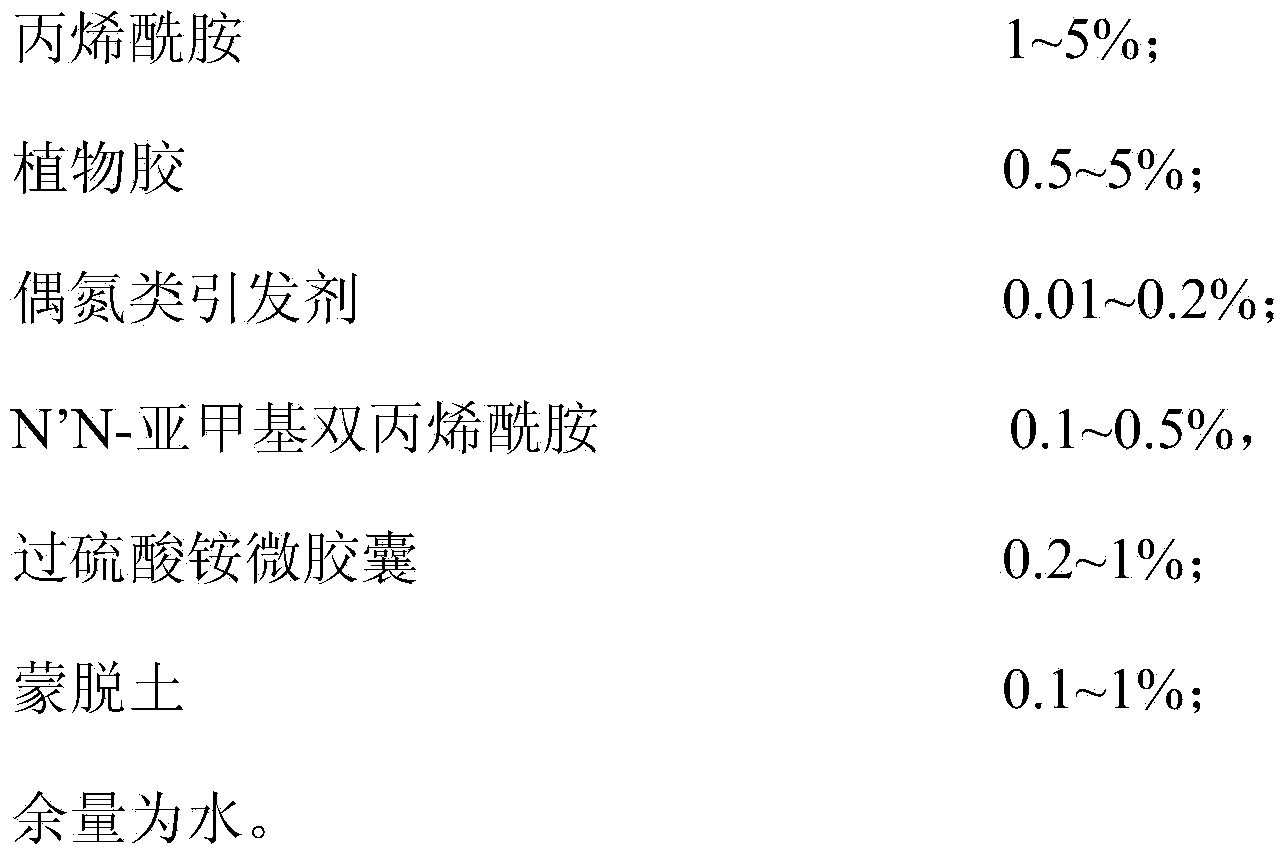

Embodiment 1

[0024] 20kg of acrylamide, 1kg of azobisisobutylamidine hydrochloride, 1kg of cross-linking agent N'N-methylenebisacrylamide, 49kg of carboxymethyl guanidine with a molecular weight of 1 million and 3kg of sodium montmorillonite Add it into 900kg of water, stir and mix evenly, and then add the above mixture together with 20kg of ammonium persulfate microcapsules into the pressurized operation column. After waiting for 60 minutes, the chemical plugging rubber plug will be formed in the pressurized operation column.

[0025] Experiments have measured that the pressure bearing capacity of the chemical plugging rubber plug of this embodiment is 20 MPa, and the rubber plug degrades after 5 days.

Embodiment 2

[0027] 49kg of acrylamide, 1.9kg of azodicyanovaleric acid, 3kg of N'N-methylenebisacrylamide, 30kg of xanthan gum with a molecular weight of 1 million and 4kg of sodium montmorillonite were added to 860kg of water and stirred, Then above-mentioned mixture and 49kg ammonium persulfate microcapsules are joined in the working column under pressure. After waiting for 120 minutes, the chemical plugging plug is formed in the working string under pressure.

[0028] Experiments have measured that the pressure bearing capacity of the chemical plugging rubber plug of this embodiment is 40 MPa, and the rubber plug degrades after 7 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure endurance | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com