Lightweight high-strength air-entrained concrete prepared by using glass powder and method thereof

A technology of air-entrained concrete and glass powder, which can be used in applications, household utensils, ceramic products, etc., and can solve problems such as environmental pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Grind kaolin tailings (dried to moisture content ≦1%) until 200-mesh sieve is 3.93% kaolin tailings powder; crushed glass is ground to 325-mesh glass powder, sieve is 1.19%; The quicklime is ground to a 200-mesh sieve with 11.88%, the effective CaO content of the lime is 84.62%, the digestion time is 7min, and the digestion temperature is 90°C; the 200-mesh gypsum sieve is 6.2%.

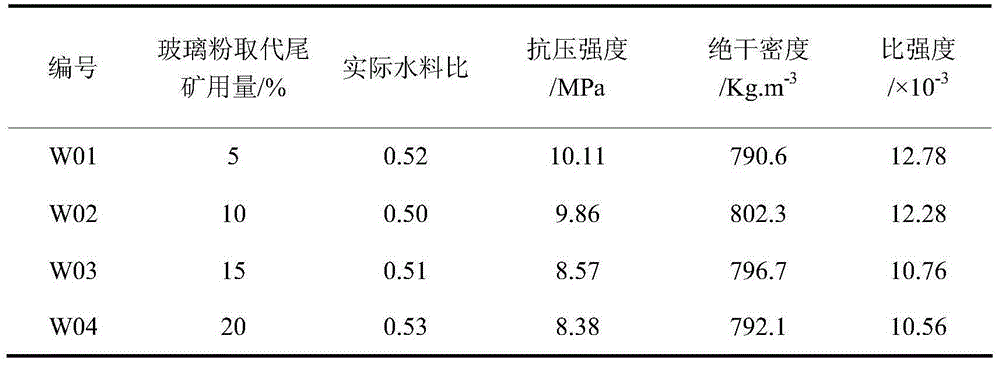

[0036] (2) According to the mass percentage, the raw materials prepared in step (1) are 60% of kaolin tailings powder, 5% of glass powder, 9% of P.O42.5 cement, 24% of quicklime, and 2% of gypsum, plus the above mixed dry materials 0.12% of the total mass of aluminum powder paste and 52% of warm water at 45°C, plus an inorganic salt admixture of 0.25% of the total mass of the calcareous material CaCl 2 . First mix kaolin tailings powder, glass powder, gypsum and warm water and stir slowly for 60s, then add cement and stir slowly for 60s, then add inorganic salt admixture, quicklime and st...

Embodiment 2

[0042] (1) Grind kaolin tailings (dried to moisture content ≦1%) until 200-mesh sieve is 4.74% kaolin tailings powder; cullet is ground to 325-mesh glass powder, sieve is 2.87%; The quicklime is ground to 12.69% on a 200-mesh sieve, the effective CaO content of the quicklime is 80.33%, the digestion time is 6 minutes, and the digestion temperature is 95°C; the gypsum fineness is 6.2% on a 200-mesh sieve.

[0043] (2) According to the percentage by weight, the raw materials prepared in step (1) are 55% of kaolin tailings powder, 10% of glass powder, 8% of P.O42.5 cement, 24% of quicklime, and 3% of gypsum, plus the above mixed dry materials 0.13% of the total mass of aluminum powder paste and 51% of warm water at 40°C, plus 0.20% of the total mass of the calcareous material as an inorganic salt additive CaCl 2 . First mix kaolin tailings powder, glass powder, gypsum and warm water and stir slowly for 60s, then add cement and stir slowly for 60s, then add quicklime and inorgani...

Embodiment 3

[0049] (1) Grind kaolin tailings (dried to moisture content ≦1%) until 200-mesh sieve residue is 5.49% kaolin tailings powder; cullet is ground to 325-mesh glass powder, sieve residue is 0.98%; The quicklime is ground to 200-mesh sieve with 10.42%, the effective CaO content of lime is 82.61%, the digestion time is 8min, and the digestion temperature is 92°C; the 200-mesh gypsum sieve is 6.2%.

[0050] (2) According to the percentage by weight, the raw materials prepared in step (1) are 52% of kaolin tailings powder, 13% of glass powder, 11% of P.O42.5 cement, 20% of quicklime, and 4% of gypsum, plus the above mixed dry material The total mass is 0.15% aluminum powder paste and 50% warm water at 50°C. First mix kaolin tailings powder, glass powder, gypsum and warm water and stir slowly for 60s, then add cement and stir slowly for 60s, then add quicklime and stir slowly for 60s, finally add aluminum powder paste and stir quickly for 45s, then stir slowly for 30s , to prepare a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com