Die for injection molding of thermosetting material

An injection molding and thermosetting technology, applied in the field of molds for injection molding of thermosetting materials, can solve problems such as waste waste and achieve the effect of saving thermosetting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

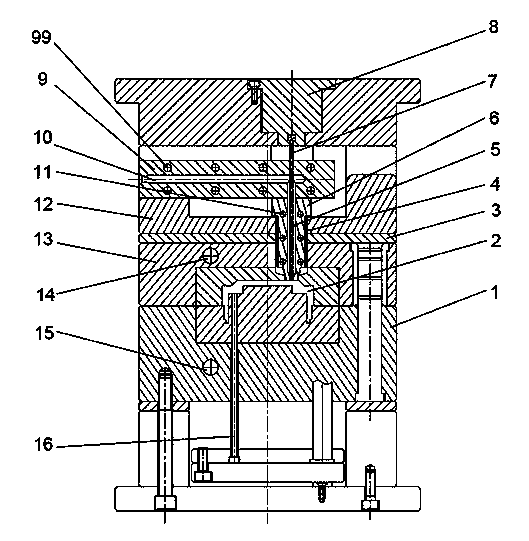

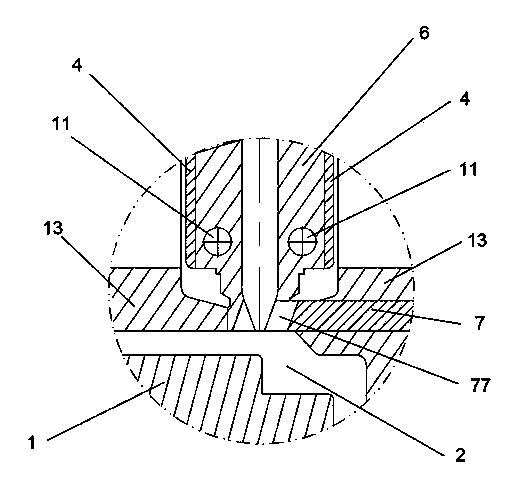

Embodiment 1

[0024] A mold for injection molding of thermosetting materials, comprising a movable mold 13, a fixed mold 1, and a runner plate 9, the runner plate is installed on the movable mold support plate 12, and a through hole is opened on the discharge runner block 6 as The discharge flow channel 5 is connected with the flow channel 10 of the flow channel plate, the heating coil 4 is installed on the outside of the discharge flow channel block, and the cooling water channel 11 is arranged in the discharge flow channel block; There is a heat insulation board 3 between the moving mold, and a cutting oil cylinder 8 is fixed on the moving mold. The output shaft of the cutting oil cylinder is fixedly connected with the cutting needle 7, and the cutting needle is installed in the inner cavity of the discharge channel 5 ; When the cutting oil cylinder pushes the cutting needle to move forward, the end of the cutting needle collides with the outlet of the discharge channel to isolate the inje...

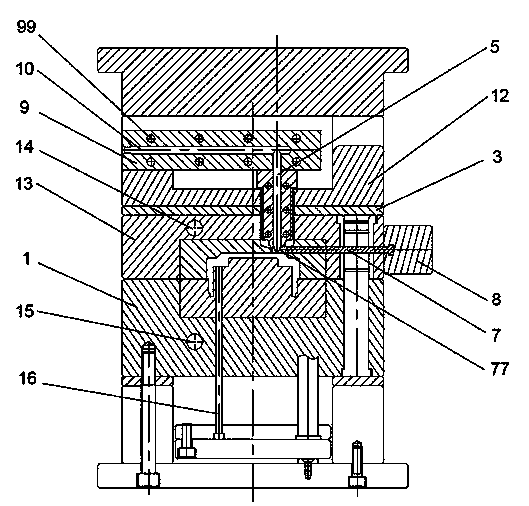

Embodiment 2

[0028] The difference between this embodiment and the first embodiment is that a cutting needle moving channel 77 perpendicular to the direction of the discharge flow channel is provided on the movable mold, and the cutting needle is installed in the cutting needle moving channel. When the cutting oil cylinder pushes the cutting needle to move forward, the end of the cutting needle collides with the discharge channel opening to isolate the injection molding cavity and the discharge channel.

[0029] In this embodiment, when the mold is ejected, the cutting oil cylinder pushes the cutting needle to move laterally to block the outlet of the outlet flow channel, and separate the outlet flow channel from the injection molding cavity, so that when the mold is ejected, the predetermined The hot material still maintains a semi-fluid state, and there is no sprue gate waste when the mold is released, which saves production materials.

Embodiment 3

[0031] The difference between this embodiment and the first embodiment is that the discharge flow channel block is made of heat insulating material, and there is no need to install heating coils outside the discharge flow channel block, and it is not necessary to add cooling water channels in the discharge flow channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com