Vertical five-shaft linkage machine tool

A five-axis linkage machine tool, vertical technology, applied in the field of machine tools, can solve the problems of machine tool rigidity, machining accuracy, work space, cutting speed, manufacturing cost, comprehensive performance that has not fully met the metal cutting requirements, difficult to obtain cutting speed, etc. Improve, facilitate high-speed cutting, improve the effect of swing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the specific implementation of examples.

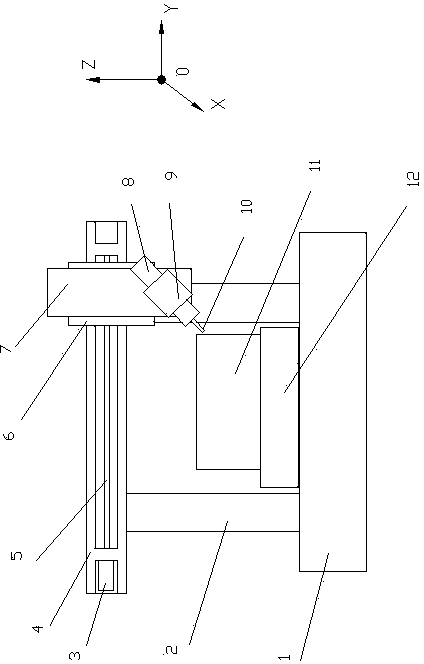

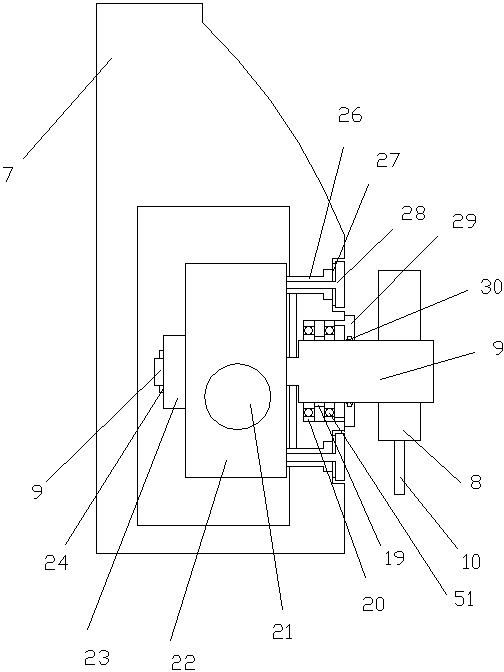

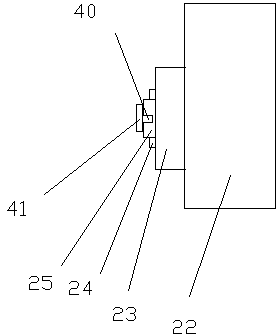

[0032] The vertical five-axis linkage machine tool includes a gantry machine frame composed of a base 1, two columns 2, and a beam 4, as well as an electric spindle chuck 9, an electric spindle 8, and a tool is installed on the electric spindle 8.

[0033] The base 1 is provided with an X-axis moving motor, a screw nut mechanism and a rotary table 12, and the rotary table 12 is arranged on the base 1 through a screw nut, and the X-axis moving motor drives the screw nut to move, and the nut of the screw nut then The rotary table 12 is driven to move along the X-axis of the base 1, and the rotary table 12 drives the workpiece 11 on the rotary table 12 to rotate 360° around the Z-axis.

[0034] The two ends of the beam 4 protrude from the column 2 to form a cornice-type gantry structure. The beam 4 is provided with a beam moving motor 3 , a ball screw 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com