A Rapid Investment Casting Method Based on Light Solidification (SL)

An investment casting and light curing technology, applied in the field of investment casting, can solve the problems of low manufacturing speed and cost of 3D printing technology, restricting the development and application of rapid investment casting, and high cost of using light curing prototypes, and achieve reliable tree connection. , Increase the wax bonding area, increase the effect of connection rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

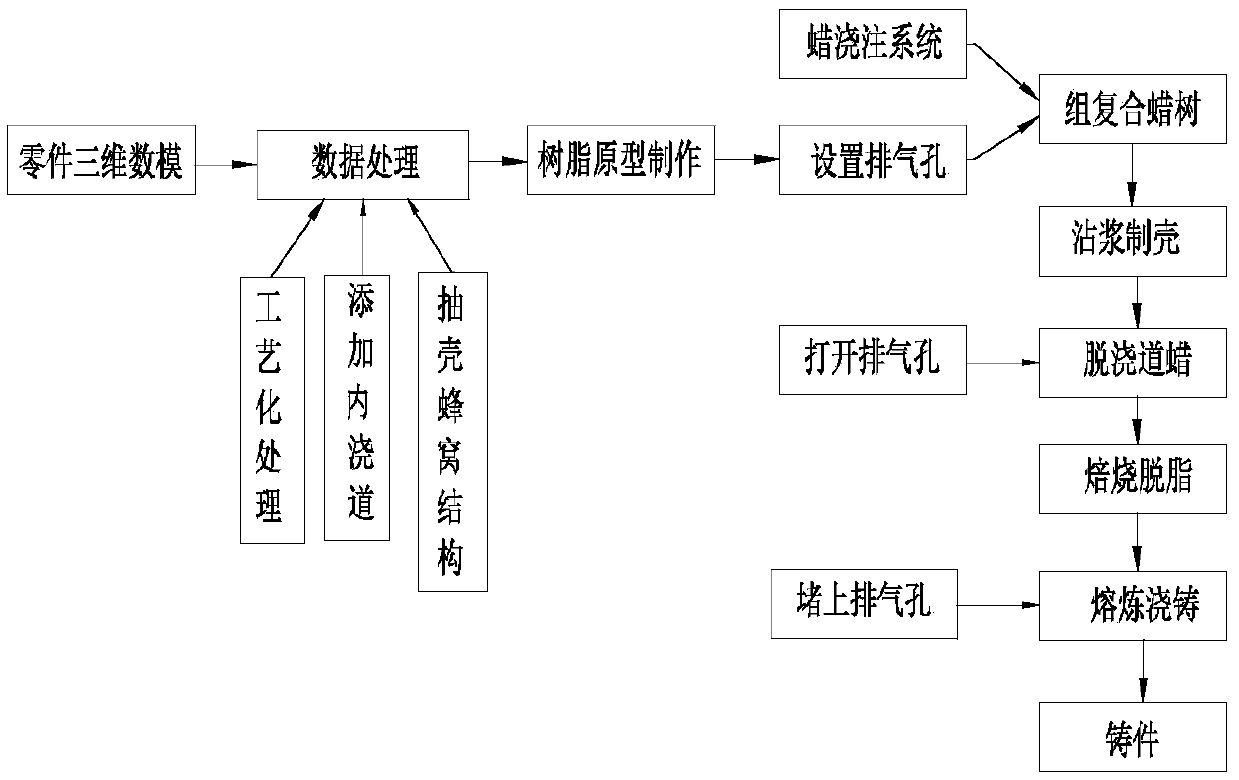

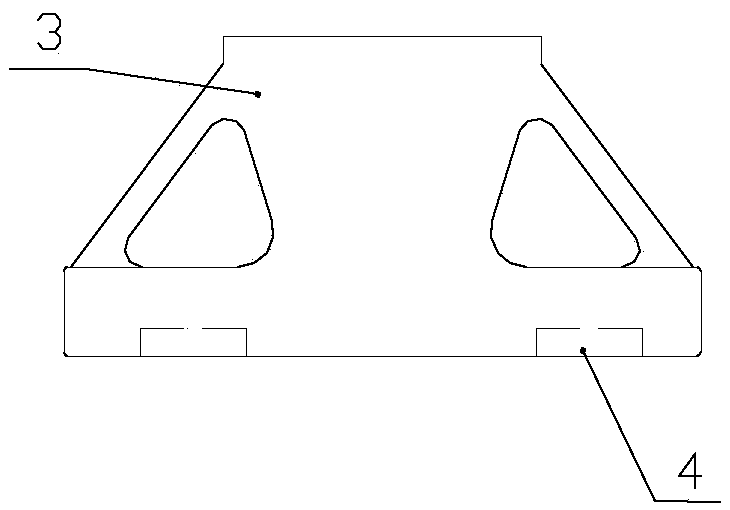

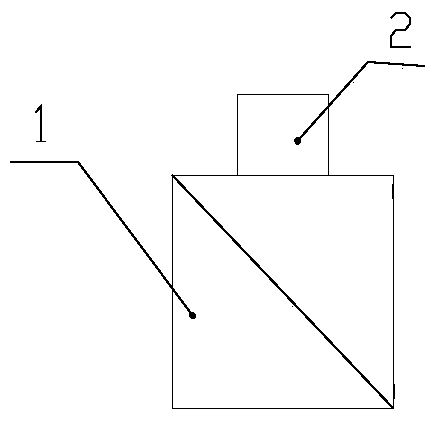

[0031] Such as figure 1 Shown is the process flow diagram of the embodiment of the present invention, and in conjunction with figure 2 , image 3 , Figure 4 As shown, a rapid investment casting method based on light curing (SL), its main operation steps and points are as follows:

[0032] 1) Acquisition of 3D digital model of cast parts:

[0033] Different from the conventional investment casting method, the rapid investment casting based on light curing (SL) does not need to make the wax pattern of the casting part, so it does not need to make the wax mold, but only needs the three-dimensional digital model of the casting part, through 3D printing Way to make a resin prototype 1 to replace the wax model. Obtaining the 3D digital model of cast parts can be done through reverse measurement of existing parts or through forward design by designers;

[0034] 2) Dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com