Cannabis Rod Separator

A technology of separator and hemp, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of long process flow, high production cost, and large amount of labor, and achieve the effect of short process, less labor and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

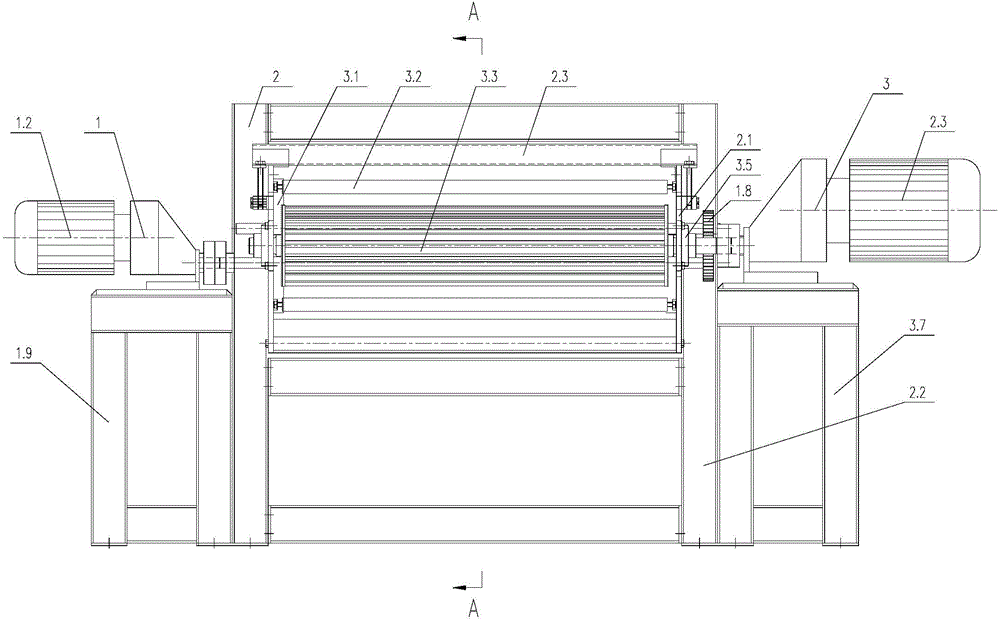

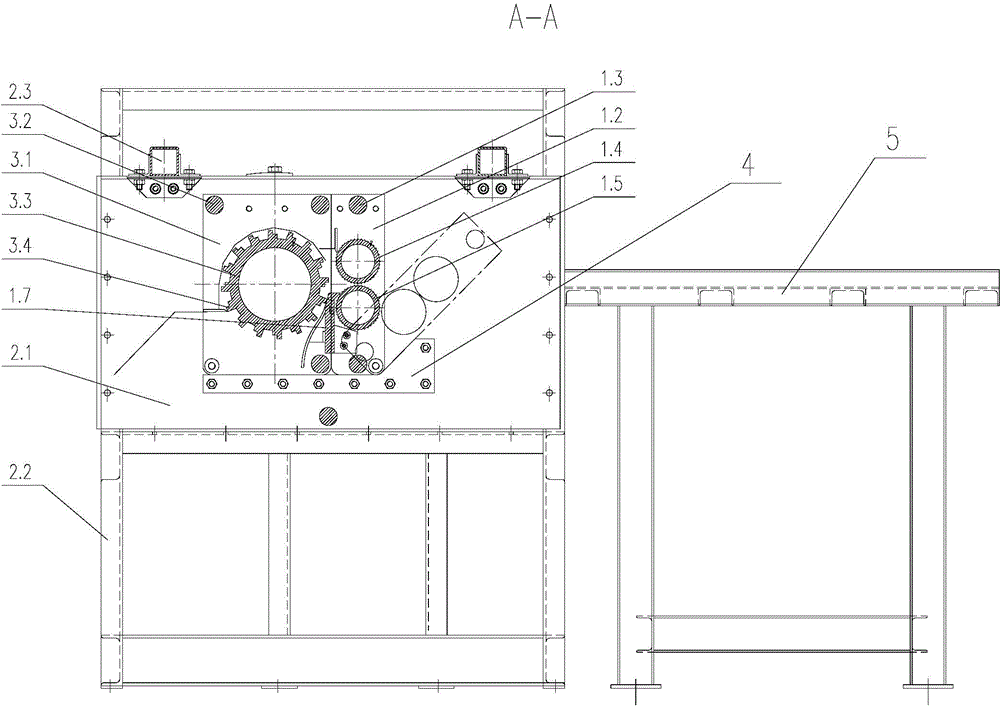

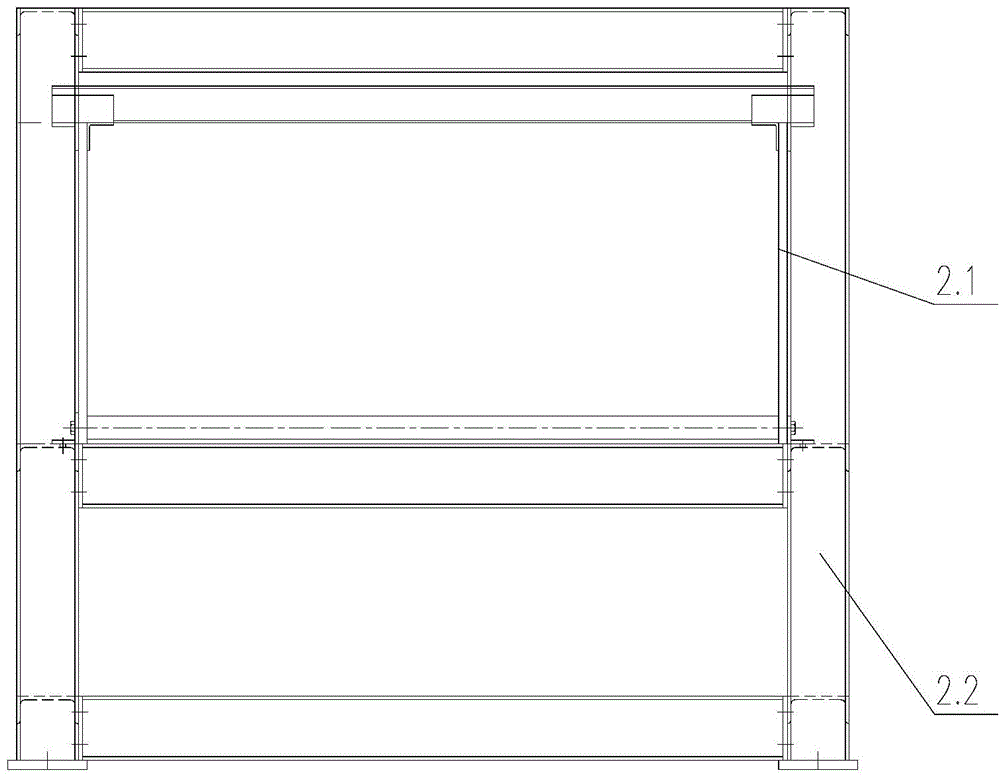

[0030] The specific embodiment of the present invention is shown in the accompanying drawings, and it is characterized in that a fixed block 4 is respectively installed on the inner side of the main frame support plate 2.1 on both sides of the upper part of the main frame 2; the striking mechanism 3 and the feeding mechanism 1 are placed side by side on the fixed block 4, and is hinged with the support plate 2.1 of the host bracket; the impact reducer bracket 3.7 is installed on one side of the host bracket 2, and the impact reducer bracket 3.7 is equipped with the impact reducer 3.6; the impact reducer 3.6 passes through the coupling It is connected with the striking mechanism 3; the feeding reducer bracket 1.9 is installed on the side of the host bracket 2, and the feeding reducer 1.1 is installed on the feeding reducer bracket 1.9; the feeding reducer 1.1 passes through the coupling and the feeding mechanism 1 phase connection; the feeding conveying platform 5 is installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com