Application of coenzyme Q10

A technology of coenzyme and use, applied in the field of application of coenzyme Q10, can solve the problems of improving pork quality, low solubility, no discovery, etc., and achieve the effect of improving meat color, increasing pork red value, and simple use method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

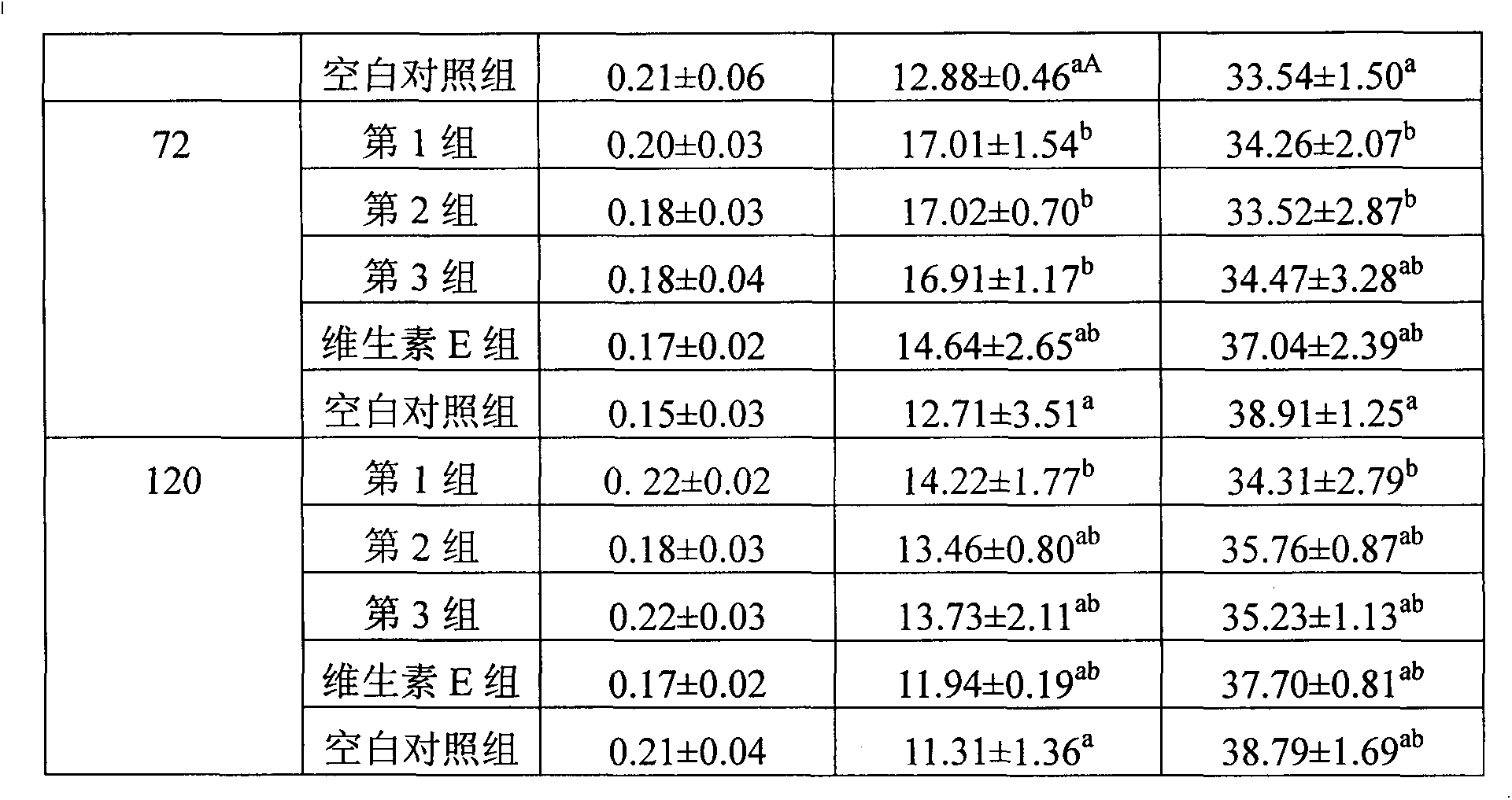

Image

Examples

Embodiment 1

[0019] The preparation of embodiment 1 coenzyme Q10 premix

[0020] Proceed as follows:

[0021] (1) Coenzyme Q10 (provided by the pharmacology laboratory of Nanjing Agricultural University) is dried to a water content of no more than 3%, and passed through a 65 mesh sieve; zeolite powder (provided by Ninghai Jiahe Chemical Co., Ltd.) is dried to a water content of no more than 5%, passed 50 mesh sieve.

[0022] (2) Take 1040g of coenzyme Q and 1960g of zeolite powder. According to the equal increment method, first place 40g of zeolite powder and 40g of coenzyme Q10 in a clean mixer, and stir and pre-mix for 5 minutes to form a coenzyme Q10 premix; then add 80g of zeolite powder into the mixer, and stir and mix for 5 minutes; Mix step by step according to the equal-increase method; finally add the remaining zeolite powder into the mixer, stir and mix for 15 minutes until the mixture is evenly mixed, and 2000 g of coenzyme Q10 premix is obtained. Packed in a clean bag at 1...

Embodiment 2

[0023] The preparation of embodiment 2 coenzyme Q10 premix

[0024] Proceed as follows:

[0025] (1) Dry the coenzyme Q10 until the water content does not exceed 3%, pass through a 65-mesh sieve, dry the corn flour until the water content does not exceed 5%, and pass through a 50-mesh sieve.

[0026] (2) Take 1060g of coenzyme Q and 1940g of zeolite powder. First, put 60g of corn flour and 60g of coenzyme Q10 into a clean mixer, stir and mix for 5 minutes to form a coenzyme Q10 premix; then add 120g of corn flour to the mixer, and stir and mix for 5 minutes; Mixing; finally, add the remaining corn flour into the mixer, stir and mix for 15 minutes until the mixture is uniform, and 2000 g of coenzyme Q10 premix is obtained. Packed in a clean bag at 1kg / bag.

Embodiment 3

[0027] The preparation of embodiment 3 coenzyme Q10 premix

[0028] Proceed as follows:

[0029] (1) Coenzyme Q10 is dried until the water content does not exceed 3%, and passed through a 65-mesh sieve, and the carrier starch is dried until the water content does not exceed 5%, and passed through a 50-mesh sieve.

[0030] (2) Take 100g of coenzyme Q10 and 1900g of starch. According to the equal increment method, first put 100g of starch and 100g of coenzyme Q10 in a clean mixer, stir and mix for 5 minutes to form a coenzyme Q10 premix; then add 200g of starch into the mixer, stir and mix for 5 minutes; Mix step by step by increasing the amount; finally add the remaining starch into the mixer and mix for 15 minutes until the mixture is evenly mixed to obtain 2000 g of coenzyme Q10 premix. Packaged in a clean bag at 1kg / bag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com