Device for controlling internal combustion engine

A technology of a control device and an internal combustion engine, applied in engine control, internal combustion piston engine, electrical control, etc., can solve the problem of inability to output PM accumulation, and achieve the effect of inhibiting accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0036] [About the structure of the system of this embodiment]

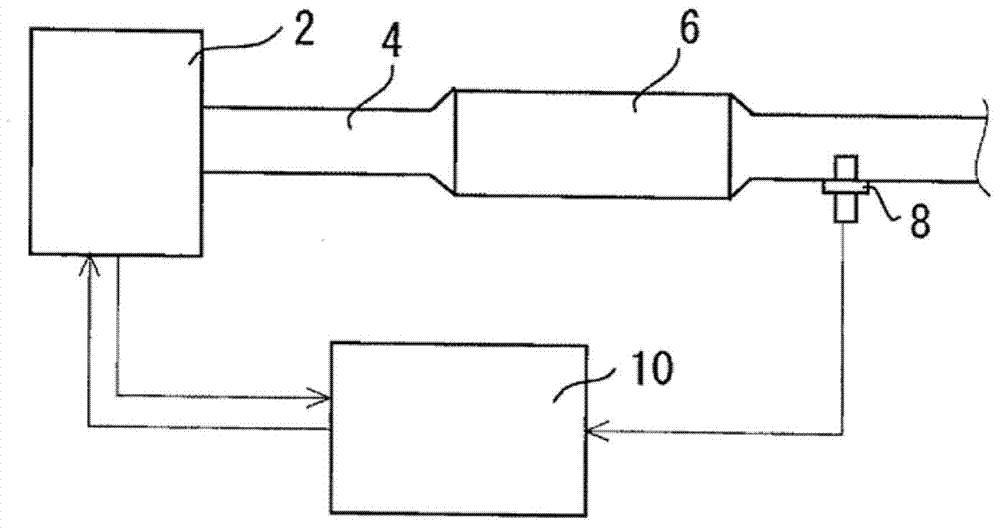

[0037] figure 1 It is a figure for explaining the overall structure of the system which concerns on this embodiment of this invention. exist figure 1 In the system shown, a DPF (Diesel Particulate filter) 6 is provided on the exhaust path 4 of the internal combustion engine 2 . The DPF6 is a filter that collects particulate matter (PM: particulate matter) contained in exhaust gas. Downstream of the DPF 6 in the exhaust path 4, a PM sensor 8 (particulate sensor) is provided. The PM sensor 8 is used to detect the amount of PM in the exhaust gas passing through the DPF 6 .

[0038] This system includes a control device 10 . Various sensors other than the PM sensor 8 are connected to the input side of the control device 10 . Furthermore, various actuators of the internal combustion engine 2 are connected to the output side of the control device 10 . The control device 10 executes predetermined programs based on...

Embodiment approach 2

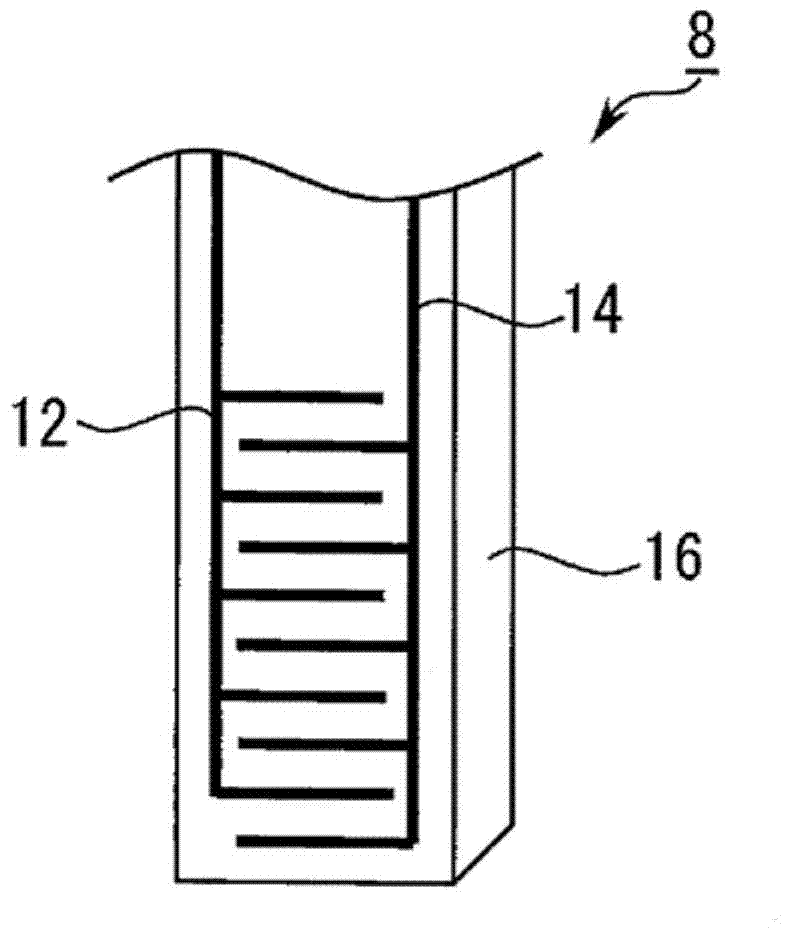

[0081] The system and the PM sensor of Embodiment 2 have the same figure 1 , figure 2 The system shown has the same structure as the PM sensor. In the system of Embodiment 2, instead of the control to form the poisoning prevention layer between the electrodes 12 and 14 after the failure detection of the DPF 6 , the poisoning prevention layer is formed by predicting the timing when the amount of PM emission increases. .

[0082] As described above, during the regeneration of the DPF 6 , for example, by increasing the temperature of the exhaust gas, the PM deposited on the DPF 6 is combusted and removed. Therefore, it can be expected that the amount of PM and poisons flowing out downstream of the DPF 6 will increase during the period in which this treatment is performed. Therefore, it is preferable to suppress the adhesion of PM and the like between the electrodes 12 and 14 during this period.

[0083] Therefore, in the system according to the second embodiment, before the ...

Embodiment approach 3

[0104] The system and PM sensor of Embodiment 3 have the same figure 1 , 2 The system shown has the same structure as the PM sensor. In Embodiment 3, control in which the controls of Embodiments 1 and 2 are combined is executed.

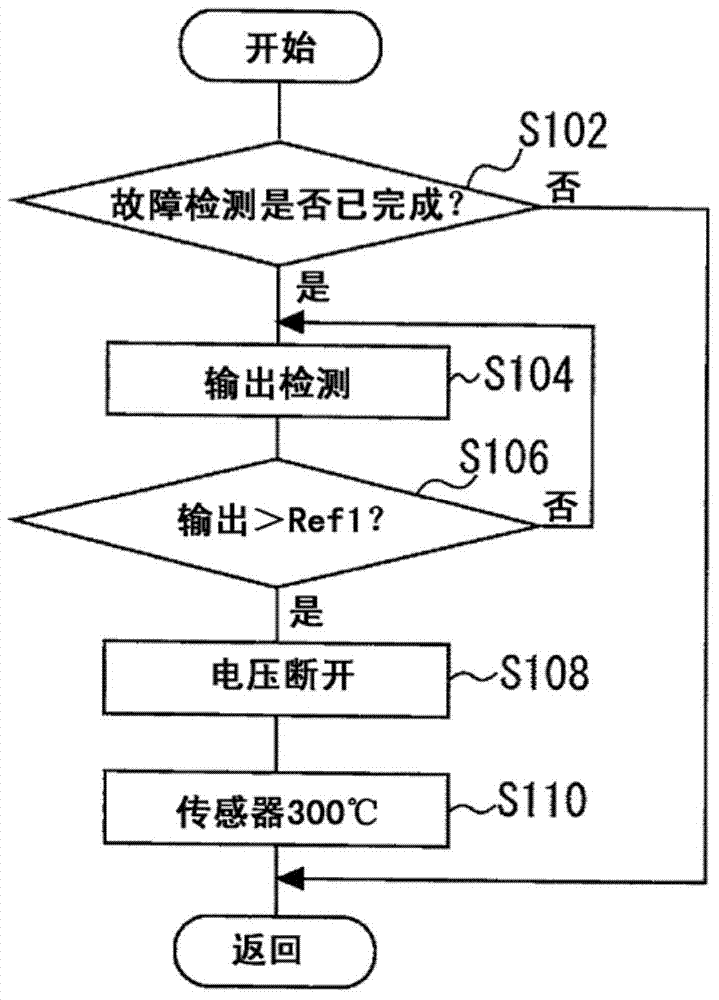

[0105] Image 6 It is a flowchart for explaining the control executed by the control device 10 in Embodiment 3 of the present invention. exist Image 6 The program, first, executes the same as that of Embodiment 2 Figure 5 The same processing as in S202 to S214. That is, it is judged whether the regeneration of the DPF 6 is predicted ( S202 , 204 ), and when the regeneration of the DPF 6 is predicted, PM removal is prohibited ( S206 ). Thereafter, until the regeneration of the DPF is completed (S208), and until a certain amount of PM is considered to have accumulated on the DPF 6, the prohibition of PM removal is continued (S210, 212), and when the accumulation of PM is confirmed, PM removal is permitted. (S214). After that, the processing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com