Method for obtaining optimal solid density for coated paper printing

A solid density, coated paper technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve the problems of high technical difficulty, the optimal solid density cannot determine the color difference between the printing proof and the standard proof, and the high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

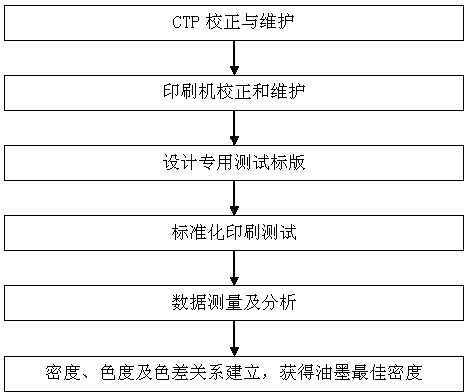

[0040] Below in conjunction with accompanying drawing, the present invention will be further described:

[0041] Such as figure 1 , figure 2 As shown, a method for obtaining the best solid density for coated paper printing includes the following steps:

[0042] Step 1. Establish a CTP process control system and complete the calibration of CTP equipment

[0043] 1-1. According to the type of CTP printing plate, monitor the pH value, conductivity, temperature of the developing solution of the CTP developing machine and the dot output value of the dot ladder of the printing plate, and establish the relationship between the dot output of the CTP printing plate and the washing conditions of the CTP developing machine matching relationship;

[0044] 1-2. Measure the 0%-100% dot data output by the CTP processor, and establish the CTP linearization compensation curve;

[0045] 1-3. Apply the CTP linearization compensation curve to the RIP of the pre-press digital process to compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com