Spectrometer and working method

A working method and spectrometer technology, applied in the field of spectral analysis, can solve the problems of increasing the volume and cost of spectrometers, and achieve the effects of low cost, reduced range requirements, and high-resolution spectral detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

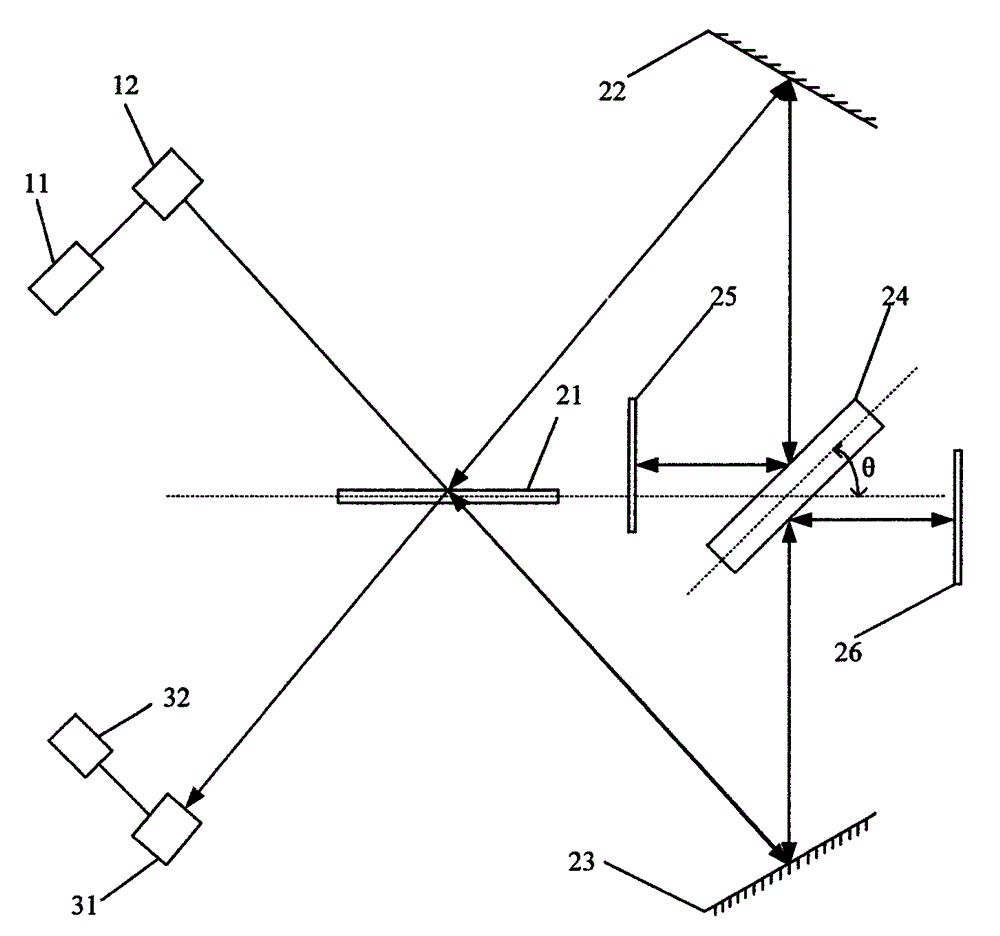

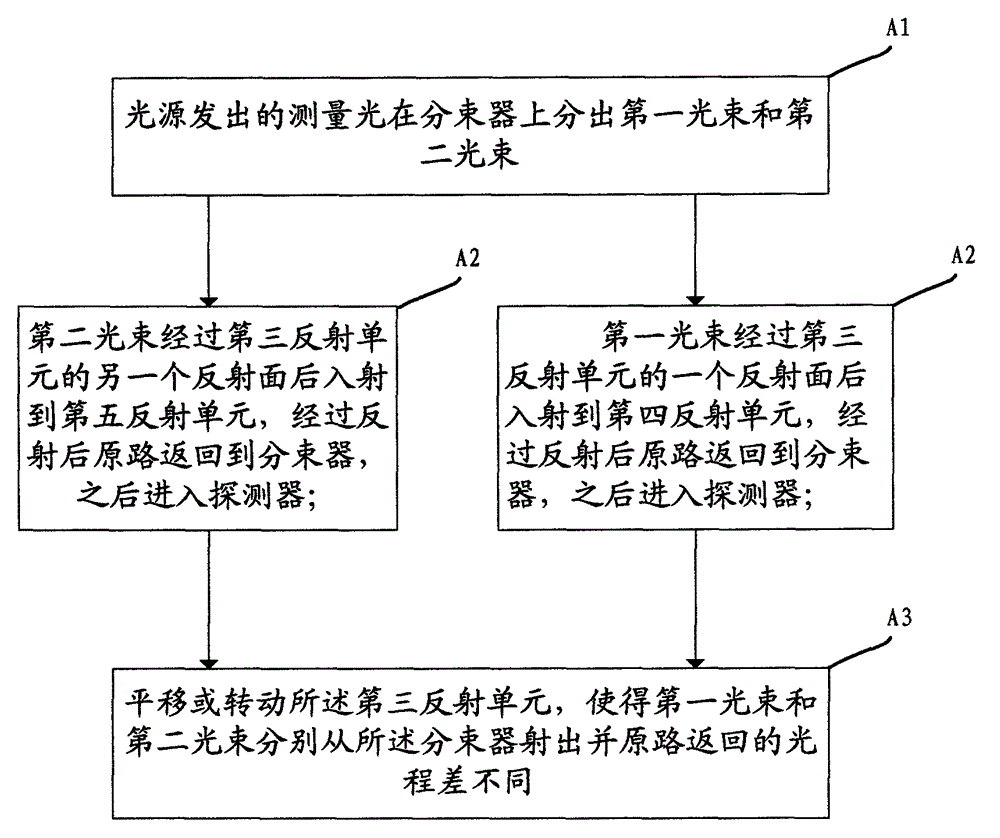

[0040] figure 1 The structural diagram of the spectrometer of the embodiment of the present invention is schematically provided, as figure 1 As shown, the spectrometer includes:

[0041] A light source 11 and a detector 32. The light source 11 and the detector 32 are prior art in the art, and will not be repeated here;

[0042] A beam splitter 21, the beam splitter 21 is arranged on the optical path of the measurement light emitted by the light source 11, and is used to split the measurement light into a first beam and a second beam;

[0043] A first reflection unit 22, the first reflection unit 22 is used to reflect the first light beam to a third reflection unit 24;

[0044] A second reflection unit 23, the second reflection unit 23 is used to reflect the second light beam to the third reflection unit 24;

[0045] The third reflection unit 24, one side of the third reflection unit 24 reflects the first light beam to the fourth reflection unit 25, and the other side reflec...

Embodiment 2

[0063] An application example of the spectrometer and working method in gas detection according to Embodiment 1 of the present invention. Specifically detect the content of gases such as carbon dioxide.

[0064] Such as figure 1 As shown, in this application example, the infrared light beam emitted by the infrared light source 11 is collimated by the parabolic reflector 12, and the collimated light beam is split by the beam splitter 21 (two beams of reflected and transmitted light); The two beams of light behind the beam are incident on the double-sided (parallel) reflective plate 24 in the direction perpendicular to the plane where the beam splitter 21 is located through the plane reflector 22 and the plane reflector 23 respectively; the reflector 22 and the reflector 23 are symmetrical about the beam splitter 21 Set, the two infrared light beams reflected by the two sides of the double-sided reflective plate 24 are retroreflected through the plane reflector 25 and the plane...

Embodiment 3

[0067] An application example of the spectrometer and working method in gas detection according to Embodiment 1 of the present invention. Specifically detect the content of gases such as carbon monoxide.

[0068] Such as figure 1 As shown, in this application example, the infrared light beam emitted by the infrared light source 11 is collimated by the parabolic reflector 12, and the collimated light beam is split by the beam splitter 21 (two beams of reflected and transmitted light); The two beams of light behind the beam are incident on the double-sided (parallel) reflective plate 24 in the direction perpendicular to the plane where the beam splitter 21 is located through the plane reflector 22 and the plane reflector 23 respectively; the reflector 22 and the reflector 23 are symmetrical about the beam splitter 21 Set, the two infrared light beams reflected by the two sides of the double-sided reflective plate 24 are retroreflected through the plane reflector 25 and the plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com