ball valve

A ball valve and valve seat technology, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problem that the moving distance of the valve seat sealing ring is too long, the moving distance of the valve seat sealing ring is shortened, and the valve seat and the ball cannot be realized. Sealing and other issues to achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

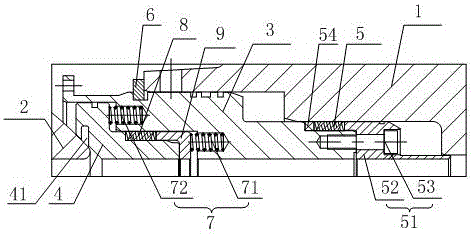

[0027] figure 1 Shown is a ball valve provided by the embodiment of the present invention, which includes a retainer 3 arranged between the valve body 1 and the ball 2, and the retainer 3 and the valve body 1 are sealed and connected by the first sealing material 5, and also includes a 3 and the valve seat 4 between the sphere 2, the valve seat 4 and the sphere 2 are sealed and connected, and the valve seat 4 and the retainer 3 are sealed and connected through the second sealing material 8; A limiting member 6 for the axial movement of the retainer 3 ; an elastic member 7 for exerting an axial elastic force is provided between the retainer 3 and the valve seat 4 , for pressing the valve seat 4 against the ball 2 . The assembly process of the ball valve of the present invention is: first install the first sealing material 5 on the holder 3, and place the stopper 6 on the outer surface of the holder 3 close to the ball 2, and put the holder 3 into the holder. In the valve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com