Assembly-type concrete shear wall structure system buckled and anchored through ring ribs

A concrete shear wall and prefabricated technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of high requirements for process equipment, multiple safety hazards, and less pouring amount for each node, so as to achieve the connection of the overall building skeleton The structure is stable, the maintenance structure of the outer wall is simple, and the effect of reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

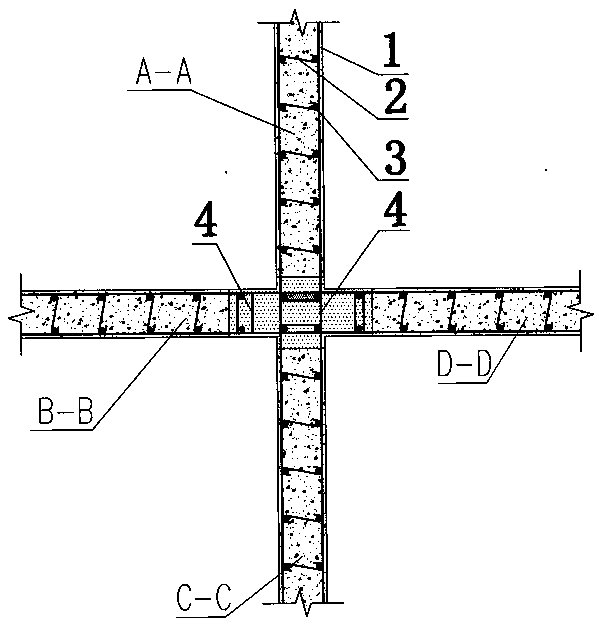

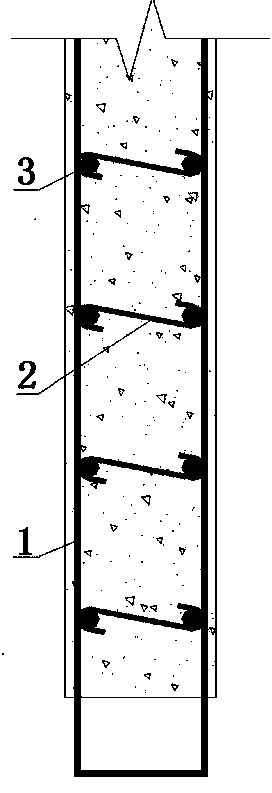

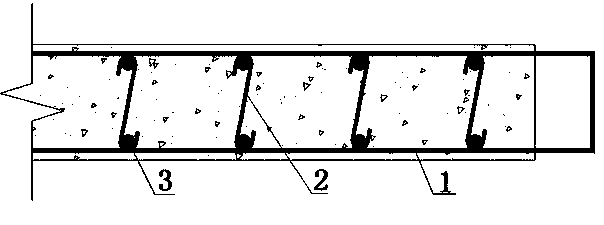

[0085] Such as figure 1 , 2 , Shown in 3, 4, 5 and 6, a prefabricated ring reinforcement fastening structure includes four prefabricated shear walls, and the prefabricated shear walls are connected by pouring concrete through the inserted reinforcement after fastening by closed stirrups; The prefabricated shear wall includes a skeleton formed by several transverse closed steel bar rings 1 and longitudinal closed steel bar rings 2. Concrete is poured on the skeleton, and the ends of the horizontal closed steel bar rings and the longitudinal closed steel bar rings are all exposed outside the concrete. The height is consistent, forming a cross structure connected by four prefabricated shear walls.

Embodiment 2

[0087] Such as Figure 7 , 7a , 7b, 7c, and 7d, a prefabricated ring reinforcement fastening structure includes three prefabricated shear walls, and the prefabricated shear walls are connected by pouring concrete through the inserted reinforcement after fastening the closed stirrups; The prefabricated shear wall consists of several transverse closed reinforcement rings 1 and longitudinal closed reinforcement rings 2. Concrete is poured on the skeleton. , forming a vertical wall with a T-shaped structure, the skeleton concrete in the prefabricated shear wall is provided with an insulation layer 5, and the insulation layer is provided with a waterproof wall surface; The sheet is connected with the skeleton formed by the transverse closed steel bar ring and the longitudinal closed steel bar ring through the anchor bar 8 .

Embodiment 3

[0089] Such as Figure 8 , 8a , 8b, 8c, and 8d, a prefabricated ring reinforcement fastening structure includes two prefabricated shear walls, and the prefabricated shear walls are connected by pouring concrete through the inserted reinforcement after fastening the closed stirrups; The prefabricated shear wall consists of several transverse closed reinforcement rings 1 and longitudinal closed reinforcement rings 2. Concrete is poured on the skeleton. , forming a vertical wall at right angles; the skeleton concrete in the prefabricated shear wall is provided with an insulation layer 5, and a waterproof wall surface is arranged outside the insulation layer; The anchor bar 8 is connected with the skeleton formed by the transverse closed steel bar ring and the longitudinal closed steel bar ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com