Method for preparing environment-friendly PVC (Polyvinyl Chloride) wire and cable material

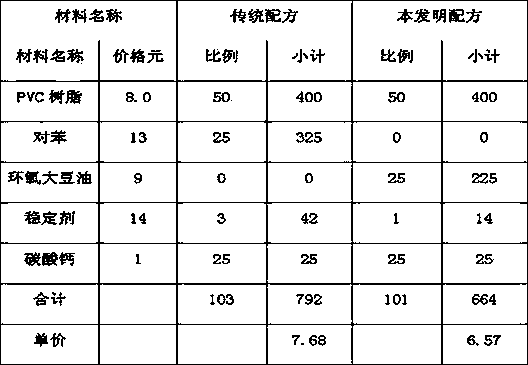

An environmentally friendly technology for wire and cable materials, applied in the field of preparation of environmentally friendly PVC wire and cable materials, can solve the problems of high formulation and production costs, increase the plasticizing time, ensure the plasticizing time, improve the pressure capacity and shear The effect of cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Choose environmentally friendly materials, including stabilizers, plasticizers, additives, and flame retardants;

[0020] 1. Stabilizer:

[0021] Stabilizers are the main source of heavy metals in environmentally friendly PVC wire and cable materials. At present, the domestic tradition uses lead-based stabilizers, which contain toxic heavy metals such as lead and zinc; the present invention adopts calcium and zinc monomer stabilizers. The stabilizer is added from 3% of the original total amount to 1%. It has ensured that the content of heavy metals such as lead, cadmium, mercury, arsenic, and hexavalent chromium in the product meets environmental protection requirements.

[0022] 2. Plasticizer:

[0023] The plasticizers are all made of biomass-derived polymer plasticizers, mainly using epoxy soybean oil and vegetable oil with an epoxy value between 6.0 and 6.4 (when the low-temperature impact embrittlement temperature is below -25°C Vegetable oil is used), w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com