Fluorine-containing nano-microsphere/fluorine-containing epoxy resin hybrid, preparation method and application thereof

An epoxy resin and nano-microsphere technology, applied in epoxy resin coatings, coatings and other directions, can solve the problems of high cost, weak adhesion, high requirements on reagents and equipment, etc., and achieve good scrub resistance and durability. Corrosive, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

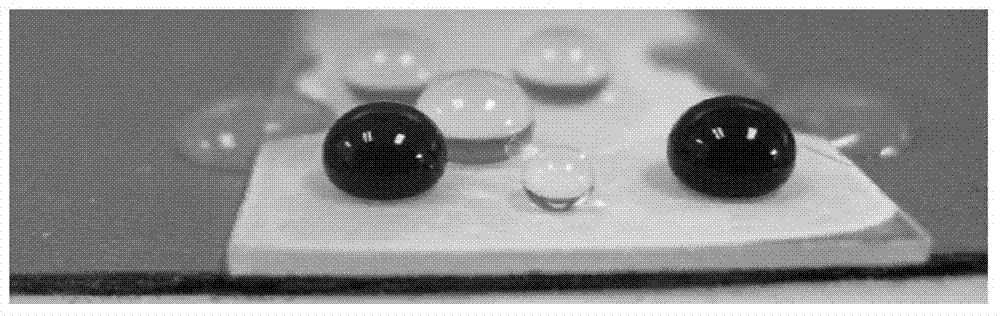

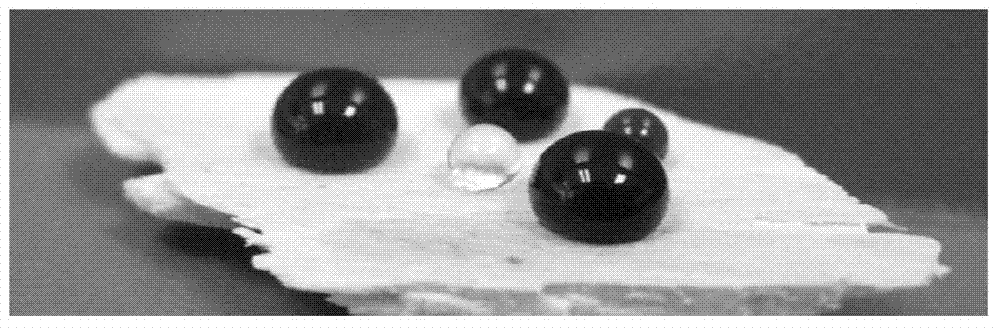

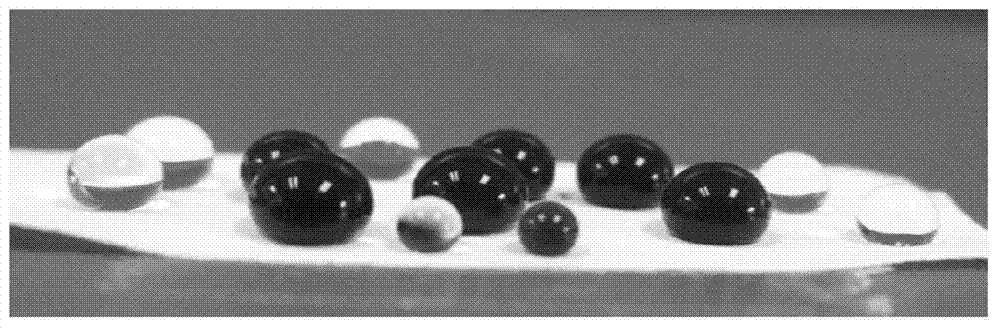

Image

Examples

Embodiment 1

[0045] (1) Preparation of a fluorine-containing nano-microsphere / fluorine-containing epoxy resin hybrid:

[0046] (1) Disperse microspheres A in solvent B, sonicate (ultrasonic power 100W, temperature 35°C) for 0.5h, and then place in an oil bath at a temperature of 80°C with a stirring speed of 100rpm. , then add epoxy resin C and catalyst D dropwise to the above system (the drop rate is 0.5g / min), after the dropwise addition, keep the above temperature for reaction for 1 hour, remove the solvent B by vacuum distillation, Then place the above system in a vacuum drying oven at 100°C and bake for 0.5 hours to obtain a hybrid of microspheres and epoxy resin grafted with epoxy groups on the surface;

[0047] Wherein the mass ratio of microsphere A, solvent B, epoxy resin C and catalyst D is 1:10:2:0; described microsphere is silica microsphere, and its particle size is 50nm; Epoxy resin C Be polyglycidyl methacrylate, its molecular weight is 1000; Solvent B is dimethyl sulfoxide...

Embodiment 2

[0057] (1) Preparation of a fluorine-containing nano-microsphere / fluorine-containing epoxy resin hybrid:

[0058] (1) Disperse microspheres A in solvent B, sonicate (ultrasonic power 500W, temperature 70°C) for 2 hours, and then place in an oil bath at a temperature of 120°C with a stirring speed of 500rpm, Add epoxy resin C and catalyst D dropwise to the above-mentioned system (the drop rate is 10g / min). The above system was placed in a vacuum oven at 150°C and baked for 2 hours to obtain a hybrid of microspheres with epoxy groups grafted on the surface and epoxy resin;

[0059] Wherein the mass ratio of microsphere A, solvent B, epoxy resin C and catalyst D is 1:100:20:0.0001; described microsphere is titanium dioxide microsphere, and its particle size is 1000nm; Epoxy resin C is phenolic Epoxy resin, its molecular weight is 1000; Solvent B is butanone; Catalyst D, and D1 is tetrabutylammonium fluoride;

[0060] (2) Dissolve the microspheres grafted with epoxy groups on th...

Embodiment 3

[0070] (1) Preparation of a fluorine-containing nano-microsphere / fluorine-containing epoxy resin hybrid:

[0071](1) Disperse microspheres A in solvent B, ultrasonically treat (300W ultrasonic power, 40°C temperature) for 1 hour, and then place in an oil bath at 110°C for stirring. The reaction temperature is 100°C, and the stirring speed is Under the condition of 100rpm, epoxy resin C and catalyst D are added dropwise to the above system (the drop rate is 8g / min). Remove the solvent B, and then place the above system in a vacuum oven at 130°C and bake for 1.5 hours to obtain a hybrid of microspheres and epoxy resin grafted with epoxy groups on the surface;

[0072] Wherein the mass ratio of microspheres A, solvent B, epoxy resin C and catalyst D is 1:80:10:0.00001; the microspheres are ferric oxide microspheres with a particle size of 50-100nm; Resin C is polyglycidyl methacrylate, and its molecular weight is 80000; Solvent B is dimethylacetamide; Catalyst D, and D1 are benz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com