Method for producing epoxy chloropropane

A technology of epichlorohydrin and dichloropropanol, which is applied in organic chemistry and other fields, can solve problems such as leakage, saponification wastewater residual pollution, and increased equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

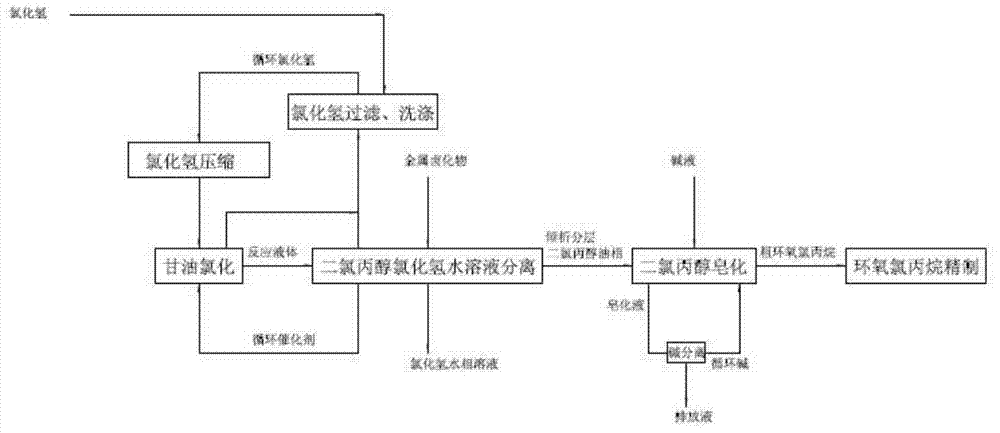

[0034] The present invention will be described in detail below in conjunction with the drawings and specific embodiments, but the drawings and specific embodiments do not constitute a limitation to the present invention. The process includes the steps of glycerin chlorination, dichloropropanol hydrogen chloride aqueous solution separation, hydrogen chloride compression, dichloropropanol saponification, epichlorohydrin refining and other steps.

[0035] (1) Glycerin chlorination liquid 95% by weight of refined glycerin is sent from the tank area to the chlorination reactor. At the same time, the catalyst storage tank is mixed with a certain amount of glycerin according to the metering and then sent to the swirl plate reactor for glycerin chlorination. The flow of hydrogen chloride is passed The flow rate of glycerin and glycerin is controlled by flow meter and regulating valve respectively to ensure the flow ratio and distribution of the reactor into the reactor. The gas raw ma...

Embodiment 2

[0051] The present invention will be described in detail below in conjunction with the drawings and specific embodiments, but the drawings and specific embodiments do not constitute a limitation to the present invention. The process includes the steps of glycerin chlorination, dichloropropanol hydrogen chloride aqueous solution separation, hydrogen chloride compression, dichloropropanol saponification, epichlorohydrin refining and other steps.

[0052] (1) Glycerin Chlorination

[0053] The liquid 95% by weight refined glycerol is sent from the tank area to the chlorination reactor, and at the same time, the catalyst storage tank is mixed with a certain amount of glycerin according to the metering and then sent to the bubble column reactor for glycerin chlorination. The flow of hydrogen chloride is matched with the flow of glycerin. The ratio is controlled by the flow meter and the regulating valve respectively to ensure that the flow ratio and distribution into the reactor ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com