Method for producing natural amino acid water-soluble fertilizer by utilizing tobacco liquid waste regenerated by paper-making process

A technology of natural amino acid and reconstituted tobacco leaves, applied in the application, fertilization device, fertilizer form and other directions, can solve the problem of high cost of production waste liquid treatment, and achieve the effects of easy popularization and use, improvement of soil structure, and large production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

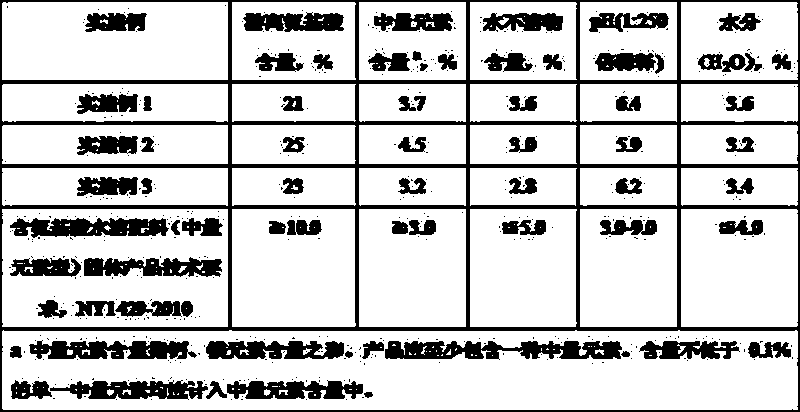

Examples

Embodiment 1

[0021] To collect the waste liquid produced by an enterprise in the production of reconstituted tobacco leaves by papermaking method to produce natural amino acid water-soluble fertilizer, the specific steps are as follows:

[0022] a) Filtration and separation of waste liquid from reconstituted tobacco leaves by the papermaking method, with a filter mesh of 40 meshes; the waste liquid from reconstituted tobacco leaves by the papermaking method can be the extraction section, evaporation concentration section, coating section, and copying molding of reconstituted tobacco leaf production The waste liquid produced by any one of the production stages or the mixed waste liquid of two or more production stages;

[0023] b) Add 0.3% protease and 10% feed-grade protein powder to the waste liquid obtained in step a) according to the mass ratio, and send it into a constant temperature reactor. The fermentation temperature is 33°C-38°C, and the reaction time is 5-20 days; The protease is...

Embodiment 2

[0030] a) Filtration and separation of waste liquid from reconstituted tobacco leaves by papermaking method, with a filter mesh of 50 meshes; the waste liquid from reconstituted tobacco leaves by papermaking method is the waste liquid produced in the extraction section of reconstituted tobacco leaf production;

[0031] b) Add 0.45% protease and 15% feed-grade protein powder to the waste liquid according to the mass ratio, and send it into a constant temperature reactor. The fermentation temperature is 33°C-38°C, and the reaction time is 5-20 days; the protease is commercially available Papain, feed grade protein powder is silkworm chrysalis powder;

[0032] c) Add 8% water-soluble calcium calcium formate to the fermented product obtained in step b) according to the mass ratio, and mix and stir evenly;

[0033] d) Filter and separate the material obtained in step c), the mesh number of the filter is 50 mesh; the liquid phase obtained by filtration and separation is sent to the ...

Embodiment 3

[0038] a) Filtration and separation of waste liquid from reconstituted tobacco leaves by papermaking method, with a filter mesh of 60 meshes; the waste liquid from reconstituted tobacco leaves by papermaking method can be the waste liquid and mixed waste liquid;

[0039] b) Add 0.6% commercially available protease, 20% bean curd and fish meal mixture to the mixed waste liquid obtained in step a) according to the mass ratio, and send it into a constant temperature reactor with a fermentation temperature of 33°C-38°C. Time 5-20 days;

[0040] c) Add 5% water-soluble calcium chelated calcium to the fermented product obtained in step b) according to the mass ratio, and mix and stir evenly;

[0041] d) Filter and separate the material obtained in step c), the mesh number of the filter is 60 mesh; the liquid phase obtained by filtration and separation is sent to the concentration equipment for low-temperature vacuum concentration, the first-effect vacuum degree is 0.05 Mpa, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com