A kind of conditioner for polycarboxylate pumping agent

A technology of polycarboxylic acid series and pumping agent, which is applied in the field of polycarboxylic acid pumping agent to achieve the effects of improving cohesion, controlling slump loss and reducing bleeding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 , Preparation of regulator for polycarboxylate pumping agent

[0024] Including the following steps:

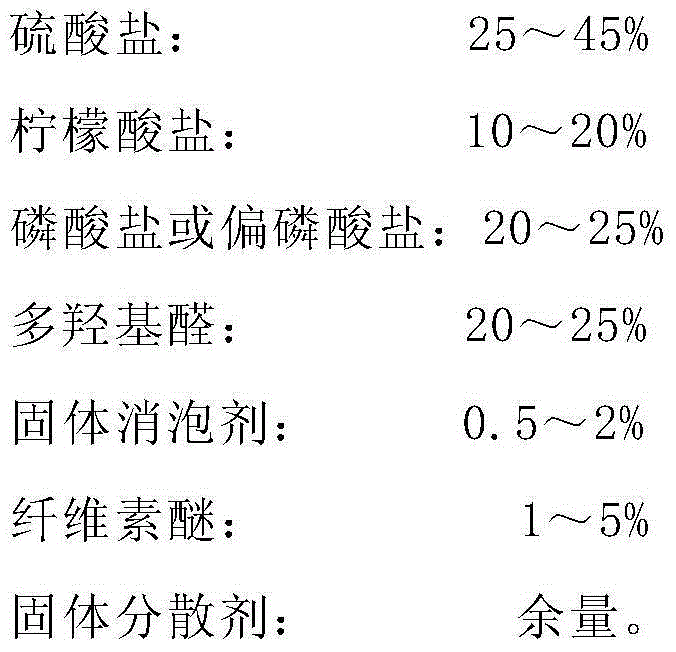

[0025] Step (1) Weigh each component according to the following ratio:

[0026]

[0027] Step (2) Mix the solid dispersant water glass, cellulose ether, and powder defoamer aluminum stearate with a high-efficiency centrifugal mixer;

[0028] Step (3) Turn on the power, start the air compressor, stop automatically when it reaches 0.4MPa, turn on the dust removal fan, and start the high-speed mixer for stirring;

[0029] Step (4) Adding sodium sulfate, polyhydroxy aldehyde, sodium phosphate and sodium citrate in sequence;

[0030] Step (5) After the blanking is completed, stir at high speed for 5 minutes; transport the mixed semi-finished product to the grinding equipment, and grind to 100 mesh to obtain.

Embodiment 2

[0031] Example 2 , Preparation of regulator for polycarboxylate pumping agent

[0032] Including the following steps:

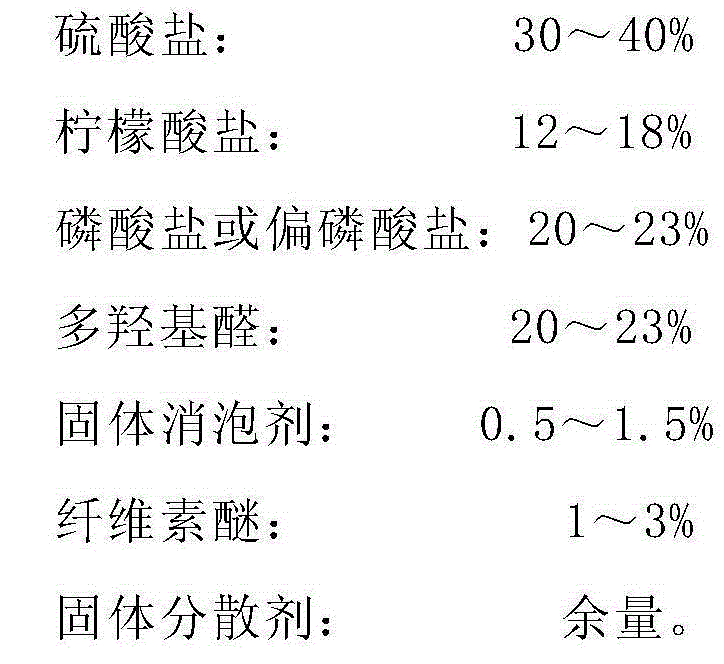

[0033] Step (1) Weigh each component according to the following ratio:

[0034]

[0035] Step (2) Mix the solid dispersant triethylhexyl phosphoric acid, cellulose ether, and powder defoamer propylene glycol fatty acid ester with a high-efficiency centrifugal mixer;

[0036] Step (3) Start the air compressor, stop automatically when it reaches 0.4MPa, turn on the dust removal fan, start the high-speed mixer, and stir;

[0037] Step (4) adding sodium sulfate, polyhydroxy aldehyde, potassium phosphate and potassium citrate in sequence;

[0038] Step (5) After the blanking is completed, stir at high speed for 5 minutes; transport the mixed semi-finished product to the grinding equipment, and grind to 100 mesh to obtain.

Embodiment 3

[0039] Example 3 , Preparation of regulator for polycarboxylate pumping agent

[0040] Including the following steps:

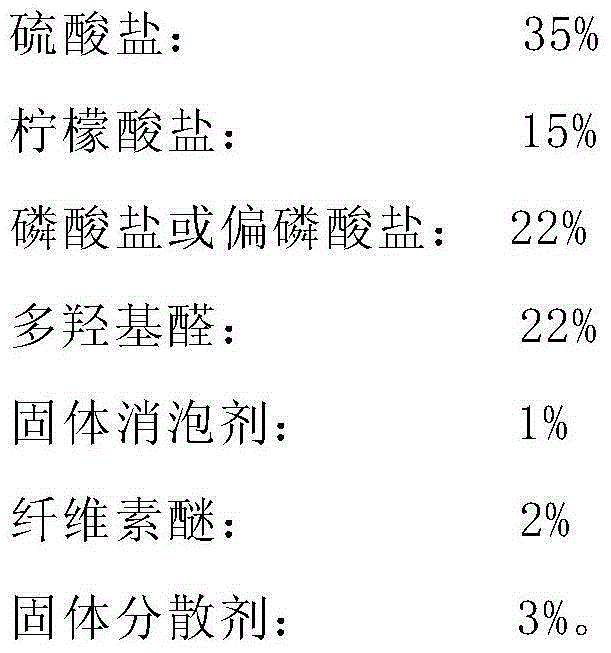

[0041] Step (1) Weigh each component according to the following ratio:

[0042]

[0043]

[0044] Step (2) The solid dispersant polyacrylamide, cellulose ether, and powder defoamer polyethylene glycol fatty acid ester are mixed with a high-efficiency centrifugal mixer;

[0045] Step (3) Start the air compressor, stop automatically when it reaches 0.4MPa, turn on the dust removal fan, and start the high-speed mixer for stirring;

[0046] Step (4) adding sodium sulfate, polyhydroxy aldehyde, sodium metaphosphate and sodium citrate in sequence;

[0047] Step (5) After the blanking is completed, stir at high speed for 5 minutes; transport the mixed semi-finished product to the grinding equipment, and grind to 100 mesh to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com