A method and device for hollow laser and electrolytic combined machining of micro ring grooves

A combined processing and laser technology, applied in the direction of electric processing equipment, accessory devices, metal processing equipment, etc., can solve the problems of insufficient flexibility and precision, and achieve the effect of reducing the critical decomposition voltage, good surface quality and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

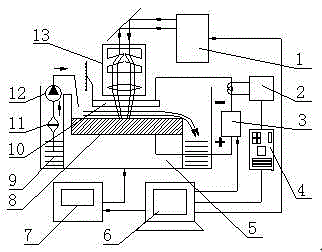

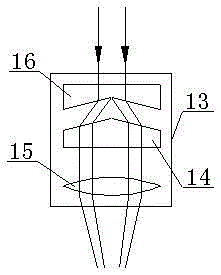

[0026] A kind of device of the present invention combines hollow laser and electrolysis to process the miniature annular groove such as figure 1 As shown, it consists of a laser shock device and an electrolytic processing device. Among them, the laser shock device is composed of computer control system, laser and laser beam variable system; the electrolytic processing device is composed of numerical control system, electrolyte, filter, micro pump, current sensor, data acquisition card, processing power supply and workbench.

[0027] Attached below figure 1 The apparatus shown illustrates in detail the practice of the invention. First, ITO conductive glass is used as the electrode for electrolytic machining, then the workpiece anode 8 is fixed above the electrolytic machining workbench 5, and finally the tool cathode 10 is fixed directly above the workpiece anode 8 and kept at a distance of 5 to 10 mm; The workpiece anode 8 and the tool cathode 10 are respectively connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com