Refrigeration apparatus disassembling separation method and disassembling separator thereof

A technology of refrigeration equipment and separation method, which is applied in the fields of solid waste removal, plastic recycling, recycling technology, etc., can solve problems such as damage to the health of operators, large noise, and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

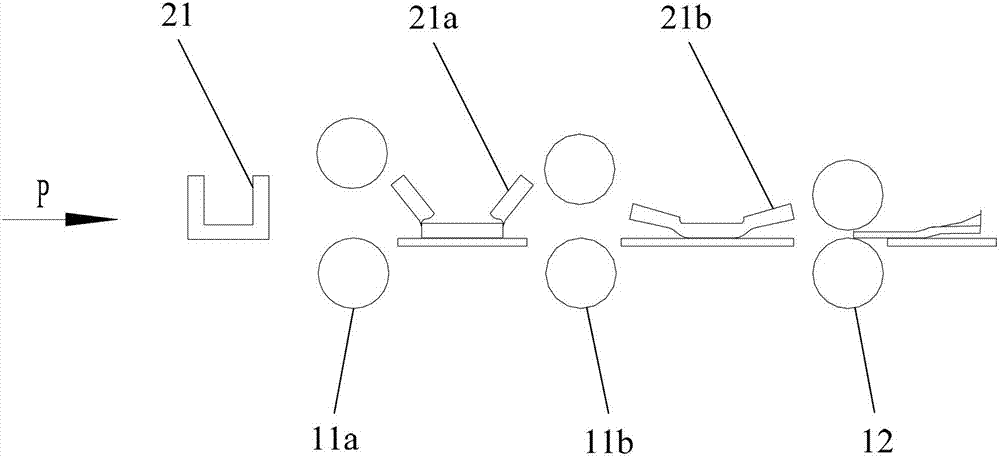

[0028] A preferred embodiment of the present invention is described below according to the accompanying drawings, Figure 1~Figure 2 A dismantling and separating method and a dismantling and separating device of a refrigeration equipment are shown. Figure 4 Indicates the composition structure of the plate body in the thickness direction of the refrigeration equipment, and the plate body includes: a steel plate 31 , a foam layer 32 and an inner container 33 . The device includes: a roller device 1 and a sealing device (not shown) for sealing the roller device. The following embodiments are described by taking waste refrigerators as an example.

[0029] The roller device 1 includes rollers arranged in the traveling direction P of the waste refrigerator, and the rollers are composed of rollers arranged up and down with gaps. The rolls comprise stretching rolls 11 and separation rolls 12, the gap between the rolls of the separation rolls 12 is less than the thickness of the min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com