Continuous digester for processing environment-friendly and energy-saving type aquatic products

A continuous digester and energy-saving technology, which is applied in the field of environmental protection and energy-saving aquatic product processing continuous digesters, can solve the problems of non-environmental protection, energy saving, waste, etc., and achieve the effects of good effect, difficulty in recruiting and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

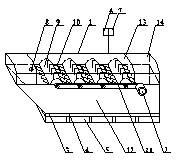

[0013] in the attached figure 1 Among them, an environmentally friendly and energy-saving aquatic product processing continuous digester, which includes the original vessel body 1 and a motor 2, is characterized in that: an interlayer 3 is provided under the vessel 1, and a heat transfer liquid 4 is arranged in the interlayer 3, Several electromagnetic ovens 5 are arranged under the interlayer 3, and a temperature controller 6 and a power controller 7 are arranged on the body 1, and the electromagnetic oven 5 is electrically connected with the power controller 7. The body 1 is provided with a temperature sensor 8 , and the temperature sensor 8 is electrically connected with the temperature controller 6 . The body 1 is provided with a plurality of rollers 9 on which a number of kelp density distribution teeth 10 are arranged, and the rollers 9 are connected with the motor 1 through a chain 11 . The body 1 is provided with a thermal insulation layer 12 , and the body 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com