Protection circuit of middle/high voltage current converter power module

A technology for power modules and protection circuits, which is applied in the field of protection circuits for power modules of medium and high voltage converters, can solve problems such as power module failure and power modules not working normally, and achieve improved safety, compact structure, and elimination of potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] When the working power supply of the power module is an AC power supply, a transformer is used as the working power supply in this embodiment. The incoming line of the primary side of the transformer can be the AC power supply outside the power module, or the AC output of the power module; the secondary outgoing line of the transformer is connected to Working power supply, the output of the working power supply is connected to the module control circuit board.

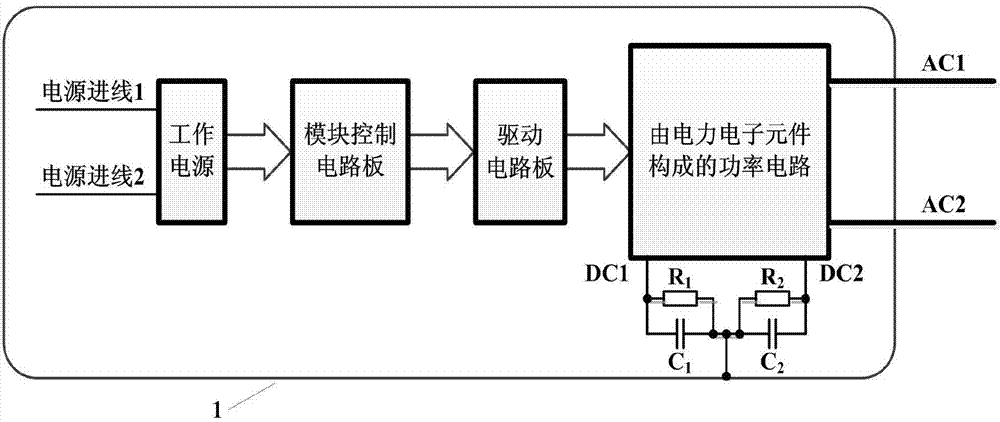

[0037] see Figure 5 As shown, the first capacitor C1 is connected between the metal casing 1 of the power module and any incoming line of the working power supply (in this embodiment, taking the incoming line 2 as an example), and at the same time, the metal casing 1 of the power module and the power module The second capacitor C2 is connected across any AC outgoing line (in this embodiment, AC2 is taken as an example), and the first capacitor C1 and the second capacitor C2 together form a protection circuit. ...

Embodiment 2

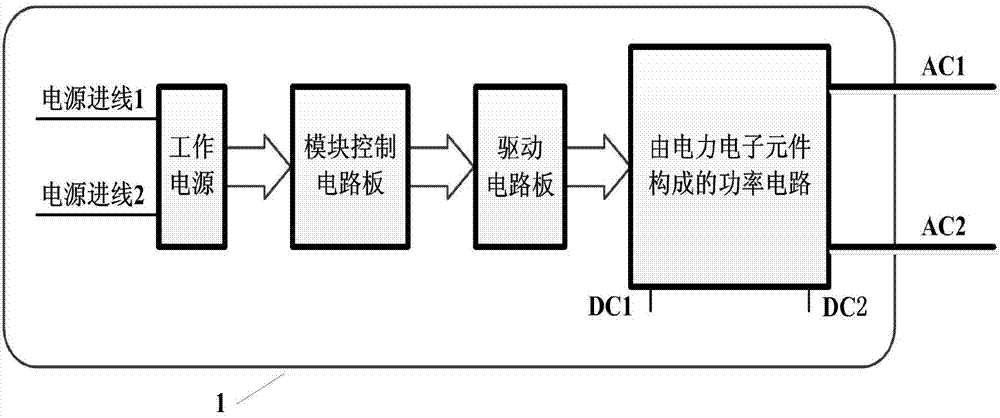

[0050] The difference between this embodiment and Embodiment 1 lies in that: the working power supply in the power module is powered by a DC power supply, taking the power supply of the DC busbars DC1 and DC2 of the power module as an example. In this case, the first capacitor C1 can be connected between the metal casing 1 of the power module and any incoming line of the working power supply. The protection circuit is simple, the structure is compact, and the original structural design of the power module is not affected.

[0051] like Figure 11 As shown, the working power supply line 1 is connected to the DC bus DC2 , the working power supply line 2 is connected to the DC bus DC1 , and the first capacitor C1 is connected between the working power supply line 1 and the metal casing 1 . like Figure 12 As shown, the first resistor R1 is connected in parallel next to the first capacitor C1 as its discharge branch.

[0052] Since the radiator is fixed on the metal casing 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com