Laminated busbars and frequency converter

A technology of laminated busbars and frequency converters, which is applied in the direction of output power conversion devices and electrical components, can solve problems such as complete machine failure, and achieve the effects of improving electrical clearances, creepage distances, and insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

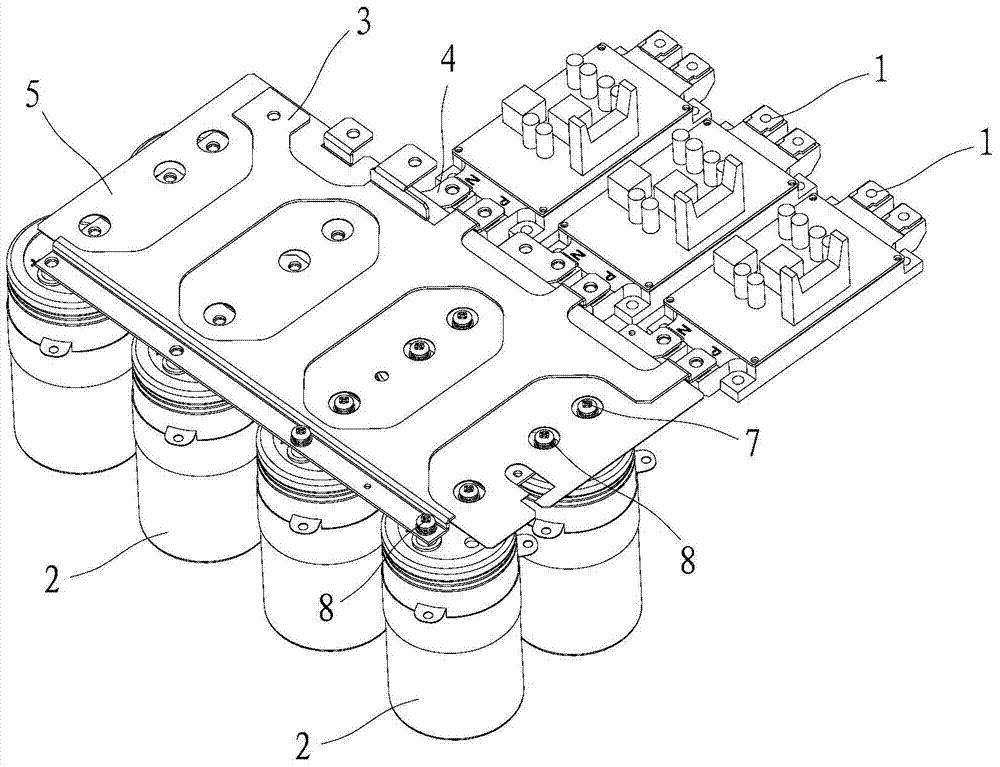

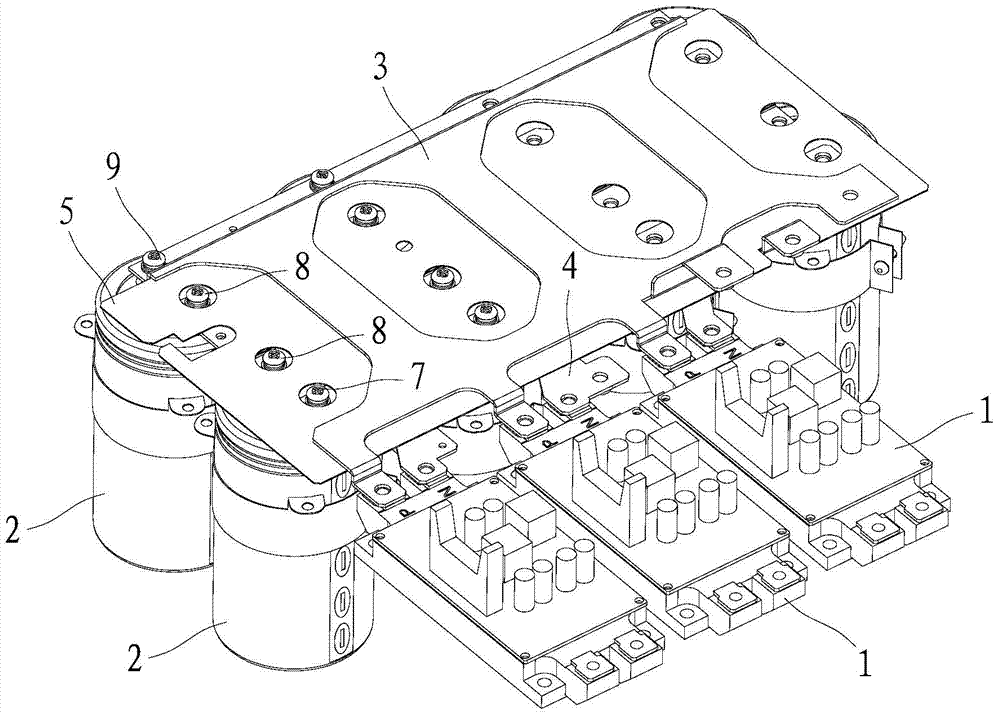

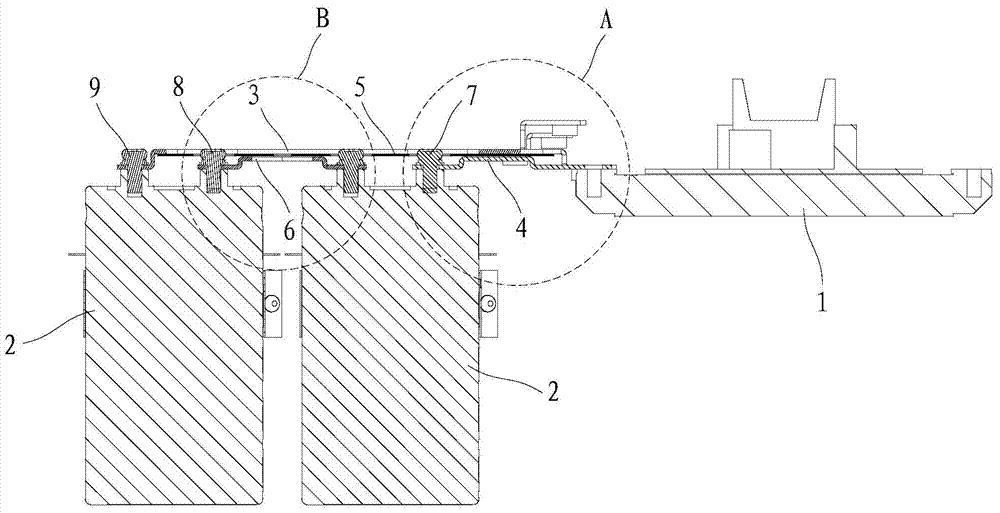

[0030] Such as figure 1 , figure 2 as well as image 3 As shown, the preferred embodiment of the present invention provides a laminated bus bar for connecting the IGBT module 1 and the capacitor 2 . The laminated bus bar includes a positive bus bar 3 , a negative bus bar 4 , an insulating plate 5 , a series-parallel bus bar 6 , a first connecting piece 7 , a second connecting piece 8 and a third connecting piece 9 .

[0031] Specifically, such as figure 1 as well as figure 2 As shown, the laminated bus bar is used to connect multiple IGBT modules 1 and multiple capacitors 2 . In this embodiment, the IGBT modules 1 have a sheet structure, and the number is three, and the three IGBT modules 1 are arranged in a stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com