LED (Light-emitting Diode) package unit, package methods thereof, and array area light source

A technology of LED packaging and LED chips, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing the manufacturing cost of LED light sources to make surface light sources, and achieve the effects of easy implementation, design freedom, and ease of mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

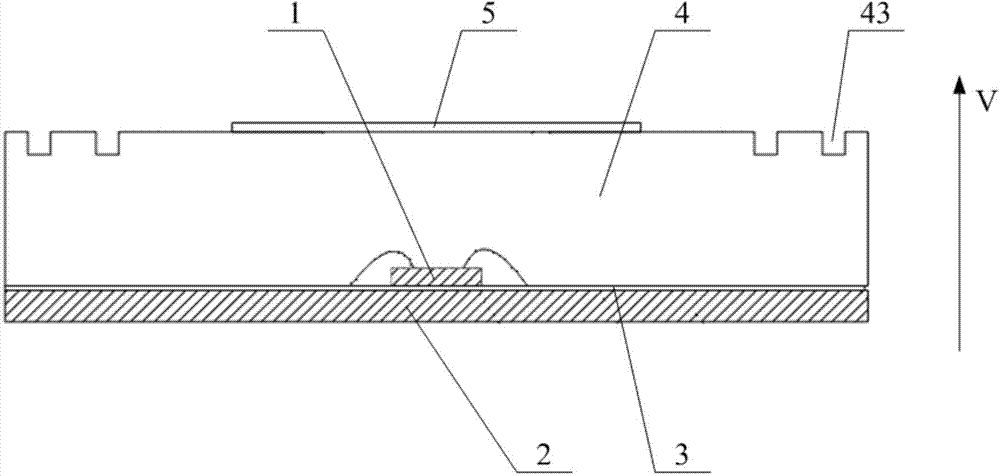

[0082] Such as figure 1 As shown, the LED packaging unit provided in this embodiment includes: an LED chip 1, a substrate 2 for mounting the LED chip 1, the substrate 2 is covered with a light-reflecting layer 3 on the end surface on which the LED chip 1 is mounted, and covers the LED chip 1 And the optical film 4 on the reflective layer 3, the optical film 4 is provided with a reflective sheet 5 corresponding to the LED chip 1 on the vertical upper surface of the optical film 4, and a scattering member for uniformly scattering the light emitted by the LED chip 1 .

[0083] It installs the LED chip 1 on the substrate 2 covered with the reflective layer 3, uses the reflective layer 3 and the reflective sheet 5 to reflect the light emitted by the LED chip 1, and uses the scattering member to refract the light emitted by the LED chip 1 and It is uniform surface scattering, so that the point light source formed by the LED chip 1 is converted into a surface light source; compared w...

Embodiment 2

[0092] The LED packaging method provided in this embodiment includes:

[0093] Step 101, manufacturing the substrate 2;

[0094] Step 102, covering the reflective layer 3 on the end surface of the substrate 2 for mounting the LED chip 1;

[0095] Step 103, mounting the LED chip 1 on the substrate 2;

[0096] Step 104, covering the LED chip 1 and the reflective layer 3 with an optical film 4, curing the optical film 4 and forming a blind hole 43 on the vertical upper surface of the optical film 4;

[0097] Step 105 , covering the position of the reflective sheet 5 corresponding to the LED chip 1 on the vertical upper surface of the optical film 4 .

[0098] The LED encapsulation method provided in this embodiment uses the LED encapsulation unit made by this method, by installing the LED chip 1 on the substrate 2 covered with the reflective layer 3, and using the reflective layer 3 and the reflective sheet 5 to emit light from the LED chip 1. The light is reflected, and at th...

Embodiment 3

[0101] The LED packaging method provided in this embodiment includes:

[0102] Step 201, manufacturing the substrate 2;

[0103] Step 202, covering the reflective layer 3 on the end surface of the substrate 2 for mounting the LED chip 1;

[0104] Step 203, mounting the LED chip 1 on the substrate 2;

[0105] Step 204, covering the optical film 4 on the LED chip 1 and the reflective layer 3;

[0106] Step 205, before the optical film 4 is cured, form a blind hole 43 on the vertical upper surface of the optical film 4 through the mold 6;

[0107] Step 206 , covering the position of the reflective sheet 5 corresponding to the LED chip 1 on the vertical upper surface of the optical film 4 .

[0108] Wherein, step 204 and step 205 can also be replaced by:

[0109] Step 304, covering the optical film 4 on the LED chip 1 and the reflective layer 3;

[0110] Step 305 , after the optical film 4 is cured, a blind hole 43 is formed on the vertical upper surface of the optical film 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com