Preparation method of a low-loss heat-free aging iron powder core

An iron powder core, thermal aging technology, applied in the direction of inorganic material magnetism, etc., can solve the problems of rising, iron powder core thermal aging, magnetic core loss, shortened device life, etc., to achieve no thermal aging, low iron powder core loss, insulation, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Select reduced iron powder (commercially available) with a purity of more than 99.0% as the raw material iron powder; the particle size distribution of the raw material iron powder is 200-300 mesh iron powder accounts for 1-10% of the weight, and the iron powder is greater than 300 mesh and less than or equal to 400 mesh It accounts for 5-40%, and the rest is more than 400 mesh iron powder.

[0028] (2) Preparation of mixed aqueous solution of phosphoric acid and chromic acid: dilute phosphoric acid (analytical pure) with water to form a phosphoric acid aqueous solution with a mass concentration of 5%, dilute chromic acid (analytical pure) with water to form a chromic acid aqueous solution with a mass concentration of 2%, and then Phosphoric acid aqueous solution mixed with chromic acid aqueous solution;

[0029] Stir and react the raw iron powder in the mixed aqueous solution of phosphoric acid and chromic acid for 4 hours, then heat up to 120°C and fry the raw iro...

Embodiment 2

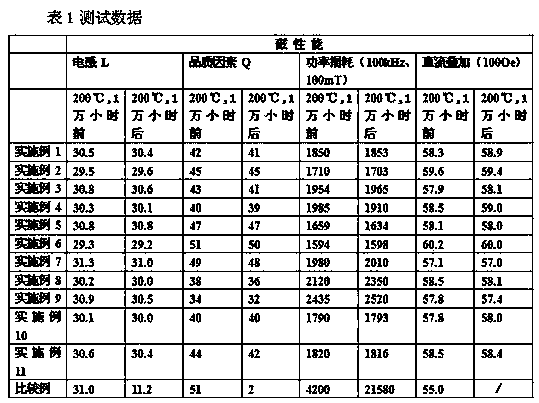

[0036] The difference between this embodiment and embodiment 1 is that the inorganic insulating agent is 2% silicon dioxide + 1% kaolin. The test results are shown in Table 1. It can be seen from Table 1 that the power loss of 100kHz and 100mT is at 1710mw / cm 3 , baked at 200°C, the loss is 1703mw / cm after 10,000 hours 3 , The loss is 40.5% of the comparative example, and there is no heat aging phenomenon.

Embodiment 3

[0038] The difference between this embodiment and Embodiment 1 is that the inorganic insulating agent is 2.5% kaolin. The test results are shown in Table 1. It can be seen from Table 1 that the power loss is 1954mw / cm at 100kHz and 100mT 3 , the loss after baking at 200℃ for 10000 hours is 1965mw / cm 3 , The loss is 46.7% of the comparative example, and there is no obvious thermal aging phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com