Normally engaged wet type clutch

A technology of wet clutches and clutch hubs, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve problems such as short life and large impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The structure of the present invention will be further described in detail in the following embodiments given in conjunction with the accompanying drawings.

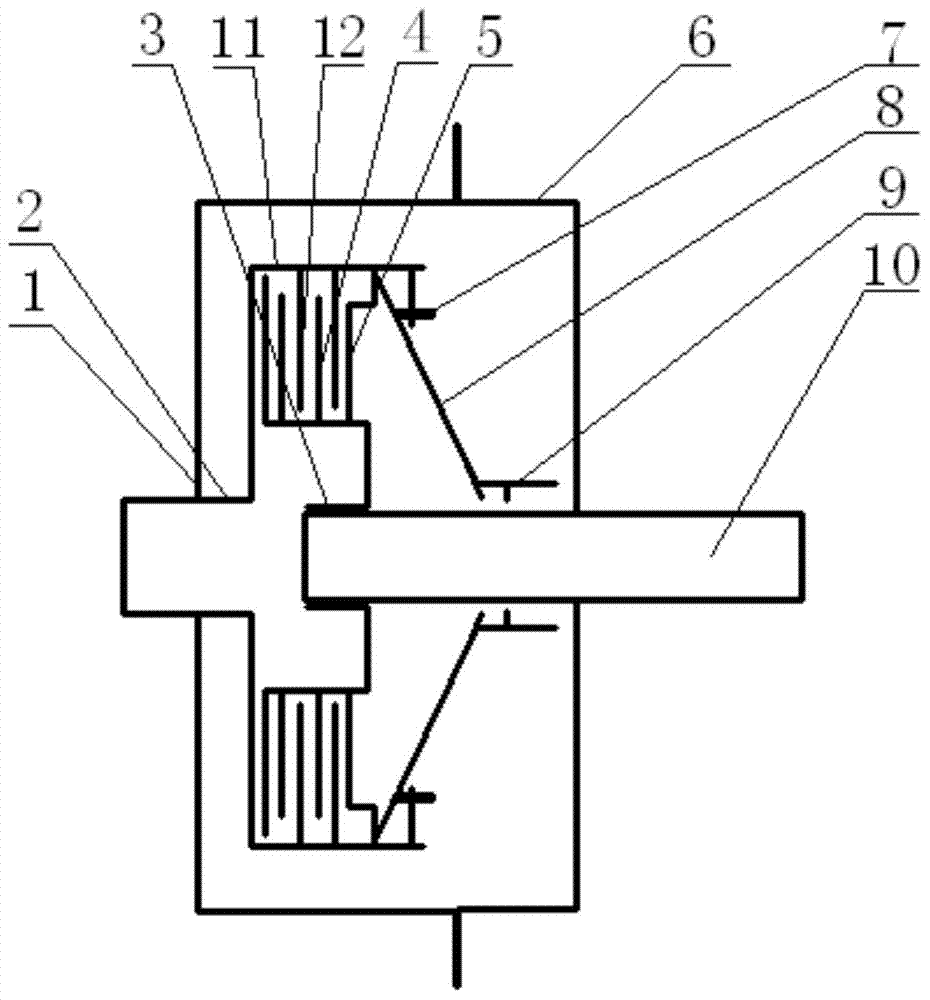

[0017] refer to figure 1 , a normally engaged wet clutch, including a closed cavity composed of a housing 1 and an end cover 6, the power output shaft 2 and the input shaft 10 are respectively arranged on the housing 1 and the end cover 6 through bearings, and the output shaft 2 The driven clutch hub 11 and the active clutch hub 3 fixed respectively on the shaft end of the input shaft 10, the driven friction plate 12 connected by splines on the inner wall of the driven clutch hub 11, and the driven friction plate 12 passed on the outer wall of the active clutch hub 3 The active friction plate 4 connected by splines, the thrust plate 5 resting on the end surface of the driven friction plate 12 and the oil pipeline for supplying lubricating oil leading into the sealed cavity;

[0018] A diaphragm spring 8 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com