Drum type metal rubber shear friction damper

A friction damper, metal rubber technology, applied in building components, anti-vibration and other directions, can solve the problems of use limitation, small vibration deformation energy consumption effect is not obvious, etc., to achieve large deformation capacity, full hysteresis curve, obvious energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

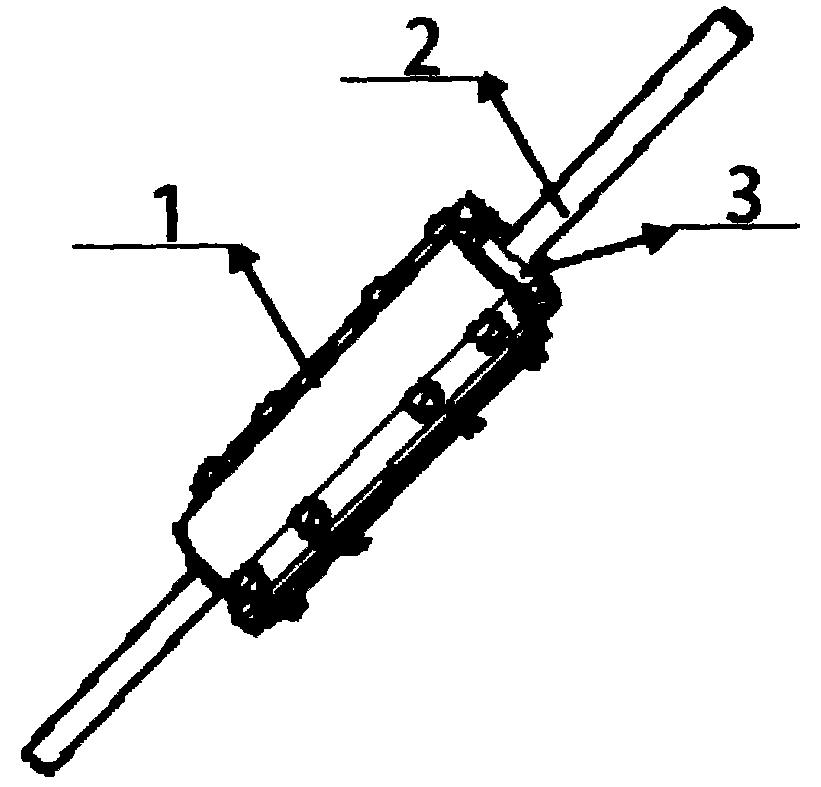

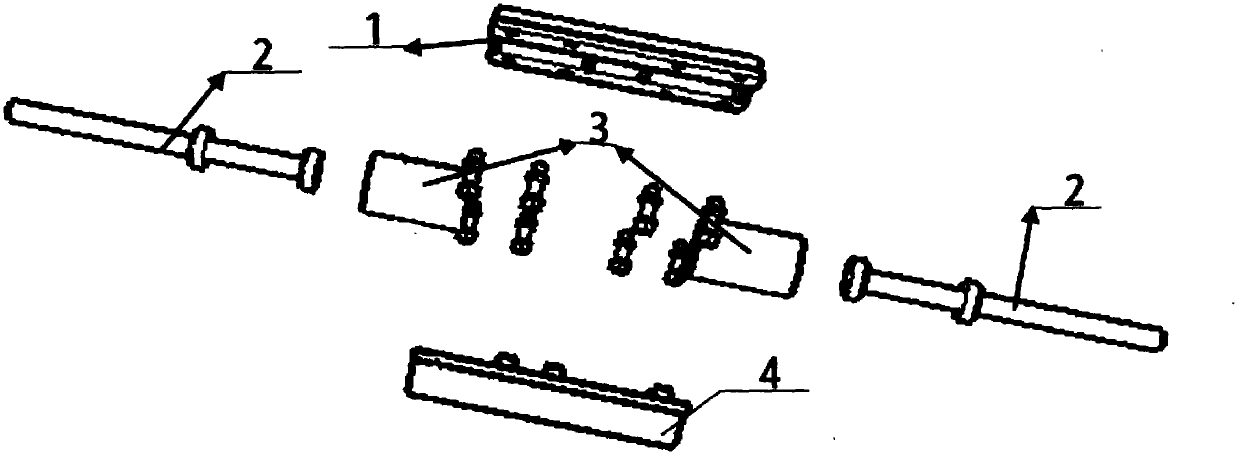

[0014] A cylindrical metal rubber shear friction damper, including an upper semicircular clamping steel sleeve 1, a lower semicircular clamping steel sleeve 4, two cylindrical metal rubber blocks 3 and two threaded steel bars 2 , two cylindrical metal rubber blocks 3 are placed in the cylinder formed by the upper and lower semicircular clamping steel sleeves 1, 4, each cylindrical metal rubber block 3 is provided with a threaded steel bar 2, the upper and lower The cylinder formed by the lower two semicircular clamping steel sleeves 1 and 4 is connected with fastening bolts; the outer side of the threaded steel bar uses bolts to apply axial pre-tightening force to squeeze the metal rubber block, so that the entire cylinder Embedded connection of type metal rubber shear friction damper.

Embodiment 2

[0016] The cylindrical metal rubber block is made by weaving the stretched helical metal wire with good quality in a certain way, and then formed by cold stamping process; the semicircular clamping steel sleeve is made of ordinary steel, and a certain number of bolts are opened. hole for connection. The cylindrical metal rubber block is directly placed inside the semicircular clamping steel casing; and the two semicircular clamping steel casings are connected by bolts; the cylindrical metal rubber shear friction damper metal rubber block and its subsidiary structure The connection is embedded and connected by the extrusion of two tightened steel sleeves and the middle threaded steel bar, and there is no other connection measure.

[0017] Experiments have proved that the cylindrical metal-rubber shear friction damper proposed by the present invention can properly improve the traditional viscous damper. By replacing the ordinary rubber with metal rubber, the traditional viscous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com