Artificial vibrator real-time monitoring and positioning system

A real-time monitoring and positioning system technology, which is applied in infrastructure engineering, architecture, building construction, etc., can solve problems such as difficult continuous supervision and vibration, low positioning accuracy, difficult accurate identification, real-time correction of deviation traceability, etc., to avoid Leakage phenomenon, effect of auxiliary control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

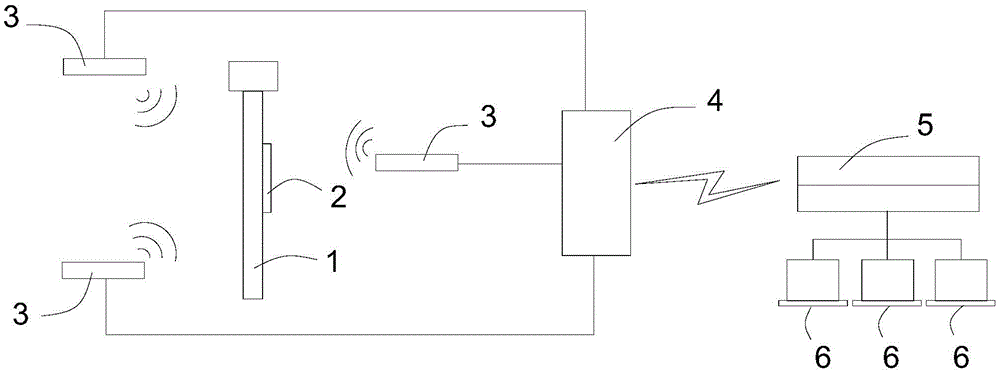

[0014] Such as figure 1 The real-time monitoring and positioning system of the artificial vibrator of the present invention includes an artificial vibrator 1, a wireless signal transmitter 2 of an ultra-wideband active signal is provided on the artificial vibrator 1, and a wireless signal transmitter 2 is provided on the wireless signal transmitter 2. A battery is provided to provide power for the wireless signal transmitting device 2 . The wireless signal transmitting device 2 sends information including its own number in real time. There are at least three wireless signal receiving devices 3 in the concrete pouring construction area (such as the warehouse surface), and the receiving range of the wireless signal receiving device 3 needs to completely cover the manual vibration construction area. The synchronization controller 4 is connected by wire to synchronize the time of the wireless signal receiving device 3 to ensure that the three-dimensional coordinates of the artifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com