Anti-static shell fabric cloth

A kind of fabric cloth and antistatic technology, which is applied in the direction of fabric, textile, textile and papermaking, etc., can solve the problems of complex preparation process of fabric cloth, high cost, and inability to meet the mass production of fabric cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

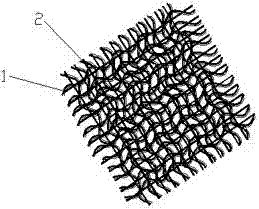

[0014] figure 1 It is a schematic diagram of the structure of the antistatic fabric according to the embodiment of the present invention; the fabric is prepared by the warp and weft weaving process. It is a blended fiber sliver of natural cotton sliver and conductive fiber sliver. The conductive fiber sliver is a composite fiber sliver, and its main components are carbon black particles and PVC particles.

[0015] In the antistatic fabric mentioned in the present invention, the blending ratio of the polyester fiber strips and the conductive fiber strips in the warp 1 is 80%-90%: 10%-20%, and the wire diameter is about 0.09-0.1mm; The blending r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com