Method for resisting lead ion depletion of lead electrolyte

A lead electrolyte, lead ion technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of short production cycle, low metal recovery rate, and many varieties of intermediate products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution provided by the present invention will be explained in detail below in conjunction with the examples, but it is not intended to limit the protection scope of the claims of the present invention.

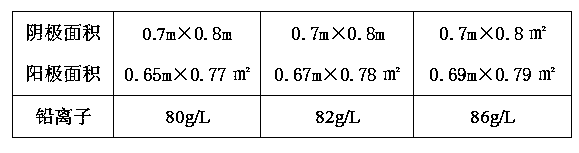

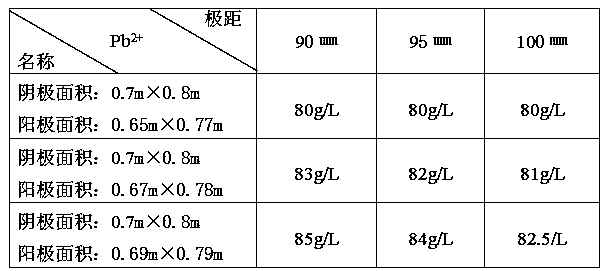

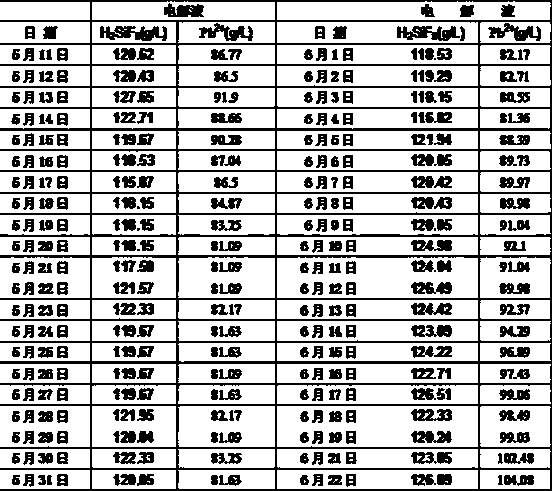

[0017] In the following examples, the raw material used is a silver anode plate made of crude lead, the grade of the lead anode plate: Pb: 88-92%, Sb: < 4-5%, Bi: < 4-6%, Cu: < 0.06%, Sn: < 0.035%, As: < 1.5%, control the temperature of the electrolyte at 45°C, the flow rate of the electrolyte: 25L / min, the electrolytic density, 200-210A / ㎡, the additives and types remain unchanged, by adjusting the anode The immersion area in the electrolytic cell and the pole distance between the anode plates are used to control the change of lead ions.

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com