A complete set of equipment for producing foam metal

A complete set of equipment and metal foam technology, applied in the field of alloys, can solve problems such as low production efficiency and energy waste, and achieve the effects of improving work efficiency and production capacity, avoiding oxidation, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

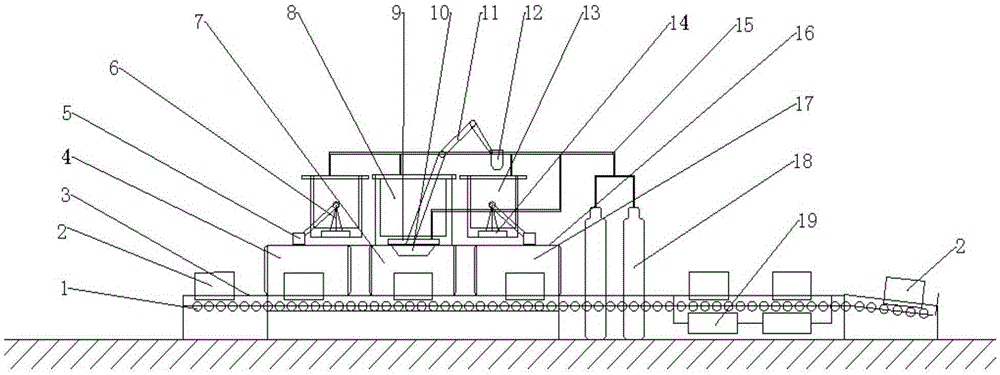

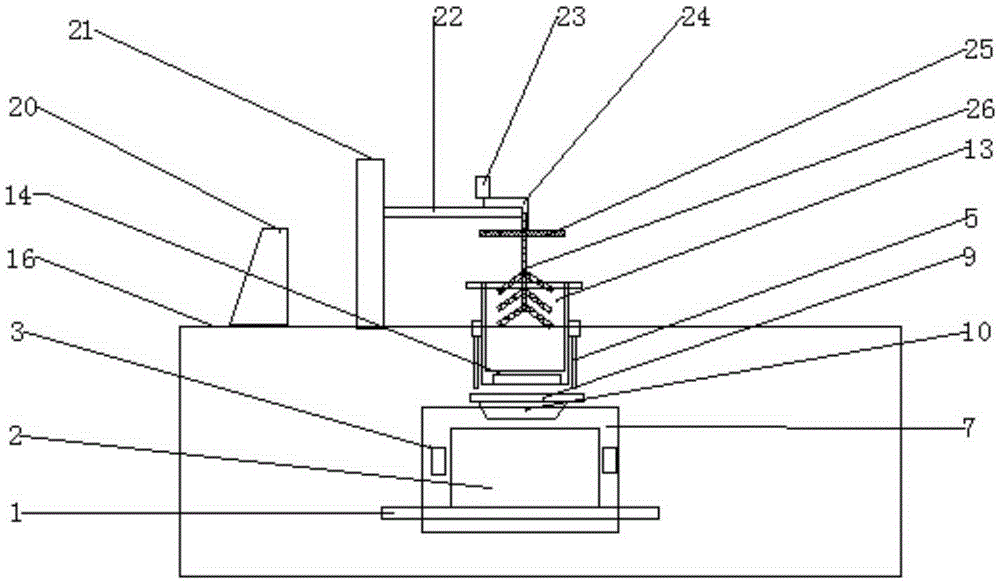

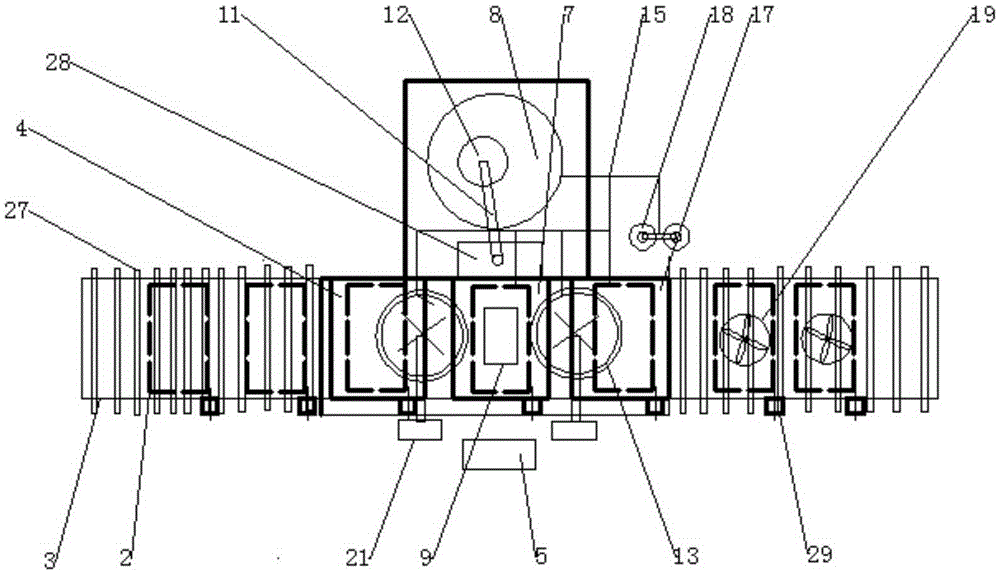

[0033] A complete set of equipment for producing foamed metals of the present invention is used to prepare foamed magnesium by a melt foaming method.

[0034] according to Figure 1 ~ Figure 3 The shown embodiment installs the complete set of equipment for producing foamed aluminum of this embodiment. Wherein, the size of the sealed box-type holding furnace is 2500mm wide, 3000mm long and 1700mm high, the size of the sealed box-type casting furnace is 2500mm wide, 3000mm long and 1700mm high, and the size of the sealed box-type molding furnace is The width is 2500mm, the length is 3000mm and the height is 1700mm. The size of the melting furnace is 2300mm in diameter and 1250mm in height. The size of the stirring furnace is 1000mm in diameter and 1250mm in height. Blade structure, the blades are bent downward to form an angle of 30° with the horizontal plane.

[0035] A kind of complete set of equipment producing foamed magnesium of the present embodiment is in application, a...

Embodiment 2

[0046] A complete set of equipment for producing foamed metal is used in the present invention to prepare foamed aluminum by a melt foaming method.

[0047] according to Figure 1 ~ Figure 3 The shown embodiment installs the complete set of equipment for producing foamed aluminum of this embodiment. Wherein, the size of the sealed box-type holding furnace is 2500mm wide, 3000mm long and 1700mm high, the size of the sealed box-type casting furnace is 2500mm wide, 3000mm long and 1700mm high, and the size of the sealed box-type molding furnace is The width is 2500mm, the length is 3000mm and the height is 1700mm. The size of the melting furnace is 2300mm in diameter and 1250mm in height. The size of the stirring furnace is 1000mm in diameter and 1250mm in height. structure, whose blades are bent downward at an angle of 30° to the horizontal.

[0048] A kind of complete set of equipment for producing aluminum foam of the present embodiment is in application, and its operation p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com